Introduction

In modern industrial inspection, 3D X-ray computed tomography (CT) is the gold standard for analyzing internal structures and detecting hidden defects in assemblies. However, beyond volumetric imaging, many manufacturers also require surface-based digital models that can be integrated into CAD or metrology software for dimensional analysis. This is where surface triangulation, the process of converting CT volume data into a 3D surface mesh (STL), becomes valuable.

At Xray-Lab, advanced CT systems and software workflows allow customers to obtain both volumetric CT data and triangulated surface models. This combination provides a complete inspection solution: detailed internal analysis from CT imaging and accurate external geometry data from surface triangulation.

Table of Contents

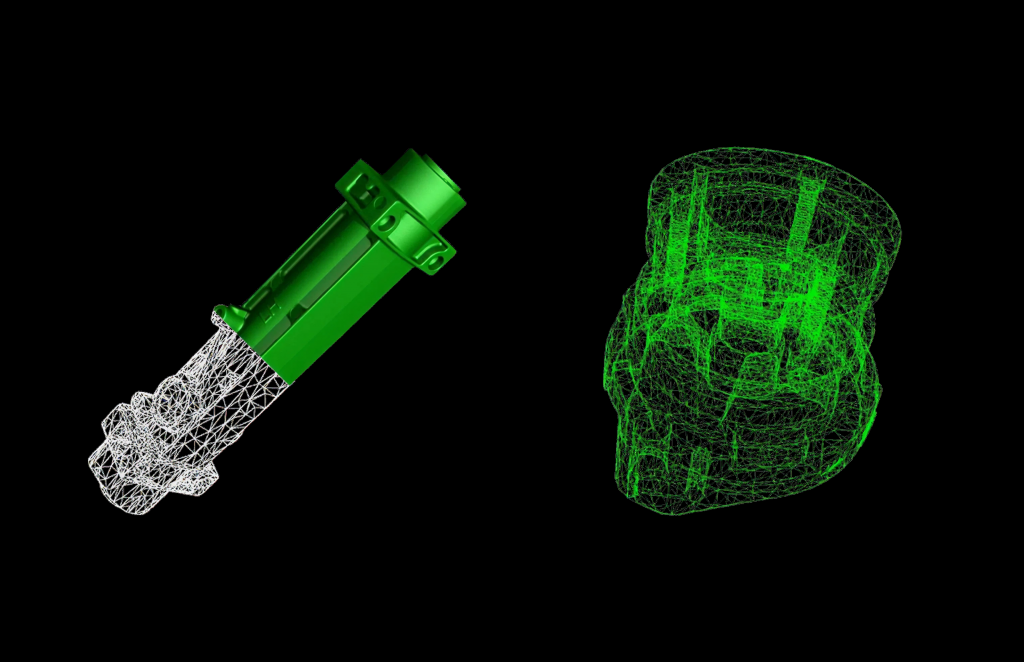

Figure. 1 3D visualization of assembly components using surface triangulation — the left image shows a partially triangulated mechanical part, while the right displays a fully triangulated 3D model for precise X-ray inspection and defect detection.

The Role of Surface Triangulation in 3D CT Workflows

A CT scan captures volumetric data represented as millions of voxels (3D pixels), each carrying grayscale values that correspond to material density. This voxel-based dataset enables comprehensive inspection — including detection of voids, inclusions, cracks, and porosity — throughout the internal volume of a component.

However, when this dataset is converted into an STL file through surface triangulation, the result is a lightweight 3D representation that contains only external geometry. This process reduces data volume and facilitates file handling, but also means that internal material information is lost. Consequently, STL models cannot be used for internal defect or porosity analysis, as these features exist only in the original volumetric CT data.

Surface triangulation therefore does not enhance the accuracy or contrast of CT imaging. Instead, it simplifies the dataset for use in downstream applications such as CAD comparison, dimensional inspection, or reverse engineering.

Applications and Advantages of Surface Triangulation

While volumetric CT data remains essential for analyzing inclusions and internal defects, surface triangulated models (STL) offer several key advantages for industrial workflows:

Application Area | Purpose | Advantage |

CAD Comparison & Metrology | Compare actual scanned geometry with design intent | Enables dimensional validation and tolerance checks |

Reverse Engineering | Create editable 3D models from physical parts | Compatible with CAD and 3D modeling software |

Digital Archiving | Store lightweight 3D representations | Easier data handling and sharing |

Assembly Analysis | Evaluate fit, alignment, and interfaces | Useful for pre-production and maintenance analysis |

Xray-Lab’s inspection systems allow seamless generation of both volumetric and triangulated datasets, ensuring customers receive the right data format for each analysis stage — from internal integrity testing to external geometry verification.

Balancing Volume Data and STL Conversion

For complete inspection accuracy, manufacturers are advised to analyze the original CT volume before exporting any surface models. The CT data enables detection of inclusions, cavities, and internal discontinuities, while the triangulated STL file supports dimensional or assembly-level evaluations.

XRAY-LAB applies this dual approach in its inspection services. Each project begins with a full volumetric CT scan to assess internal quality, followed by optional surface triangulation to deliver CAD-compatible geometry for further measurement or design integration.

Conclusion

Surface triangulation is a valuable post-processing technique that complements, but does not replace, volumetric CT imaging. It simplifies 3D data for downstream engineering use, offering significant advantages in CAD comparison, reverse engineering, and assembly verification. However, the loss of voxel density information means that analyses for inclusions, porosity, or material inhomogeneity must always be performed on the original CT dataset.

By combining high-resolution CT imaging with precise surface triangulation, XRAY-LAB enables customers to achieve both internal defect detection and external dimensional validation — ensuring complete, traceable, and non-destructive inspection of complex assemblies.

XRAY-LAB helps industries implement these advanced inspection technologies, providing fast, accurate, and non-destructive testing solutions to ensure top-notch product quality and safety.

Frequently Asked Questions

What Is Surface Triangulation in Assembly Inspection?

Surface triangulation is a technique that converts the surface of an object into a mesh of triangles, which is used to create detailed and resource-efficient 3D-models.

What Industries Benefit Most From Surface Triangulation in Assembly Inspections?

Industries such as aerospace, automotive, and electronics manufacturing benefit significantly from surface triangulation, as it helps correlate external 3D geometry with internal X-ray data, enabling more accurate defect localization, part alignment, and dimensional verification during assembly inspections.

Is Surface Triangulation Applicable to All Types of Assemblies?

Surface triangulation is especially useful for complex geometries and parts with intricate designs, which are common in critical industries like aerospace and electronics.