Introduction

In industries today, from electronics and aerospace to automotive and composites, non-destructive evaluation (NDE) is no longer optional. The demand for defect-free components, reliable quality assurance, and failure prevention has pushed modern manufacturers to embrace advanced X-ray technologies. At XRAY-LAB, we are proud to offer a spectrum of high-resolution 2D, 2.5D, and CT X-ray inspection systems engineered for precision, safety, and industrial performance.

In this blog post, we present a full catalogue of our flagship X-ray solutions, categorized by their intended applications. Whether you inspect microelectronics or heavy castings, you’ll find a system designed for your needs.

Table of Contents

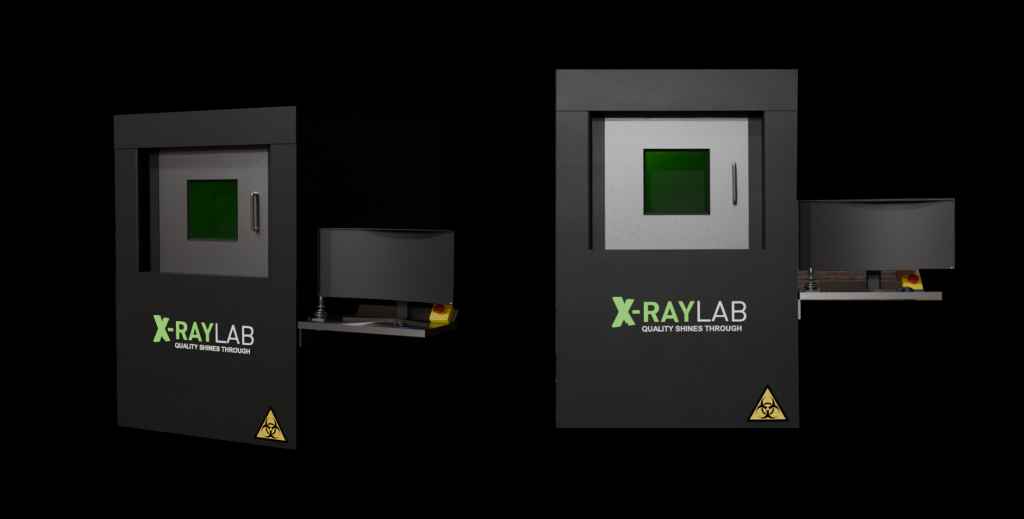

130 kV High-Resolution 2D / 2.5D (Optional CT) System

The Microscope of Electronics

This compact, high-precision system is your go-to for inspecting electronic components, printed circuit boards, plastic parts, composites, aluminum elements, welds, and small steel parts. Its design focuses on resolving very fine structures—ideal where micro-defects are critical.

Dimensions & System Specs

- Dimensions (L×W×H): 1,350 × 1,250 × 1,700 mm

- Total Weight: 1,900 kg

- Magnification: Up to 1,600×

- Power Requirements: AC 110–220 V, 50/60 Hz

- Max Power Consumption: 2.0 kW

- Operating Environment: 0 °C to 40 °C, 30–70% RH

- X-ray Tube: Closed type, 130 kV, 0.5 mA, focal spot 3 µm

- Flat panel, 130 × 130 mm, 85 µm resolution

- Manipulator: Load diameter Ø 570 mm, detection area 450 × 450 mm,

- tilt 55°, full rotation

- X-ray Emission: < 1 µSv/h

Packaging

- Plywood crate: 1,880 × 1,470 × 1,950 mm

- Total Weight: ~2,000 kg

Typical Uses

- Inspecting tiny solder joints and microvias

- Quality control of surface-mounted devices (SMD)

- Identifying voids or delamination in composite structures

130 kV High-Resolution 2D / 2.5D (Optional CaT) System

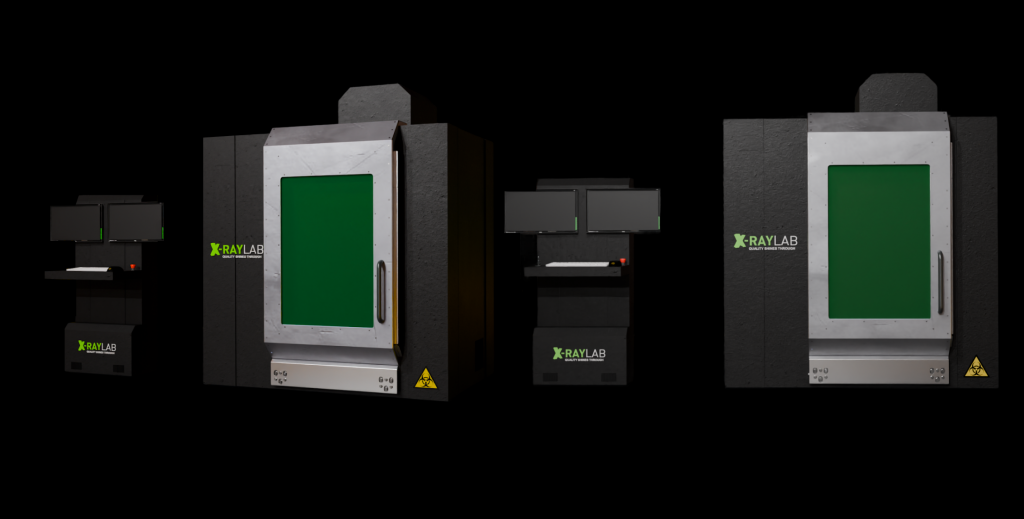

160 kV 2D / 2.5D-System (Optional CT) — For Medium Castings & Components

Ideal Applications

This model bridges the gap between micro-scale inspection and larger industrial parts. Use it for aluminum castings, thin-wall steel, plastic parts, composites, and welds.

Highlights & Technical Data

- Mini-focus X-ray tube ensures crisp imaging

- CNC 5-axis C-arm manipulator allows high flexibility in orientation

- Penetration capability: ~100 mm in aluminum, ~20 mm in iron

- Detection zone diameter: 500 mm × 800 mm

- Loading capacity: 50 kg

Dimensions & System Specs

- Machine size: 2,100 × 1,720 × 2,470 mm

- Weight: 3,800 kg

- Input: Three-phase AC 380 V ±10%, power ≤ 6.0 kW

- Detector: 17″ × 17″ flat panel, 139 µm resolution

- Environmental limits: 5–40 °C, RH ≤ 80%

160 kV X-Ray System (2D / 2.5D Optional CT)

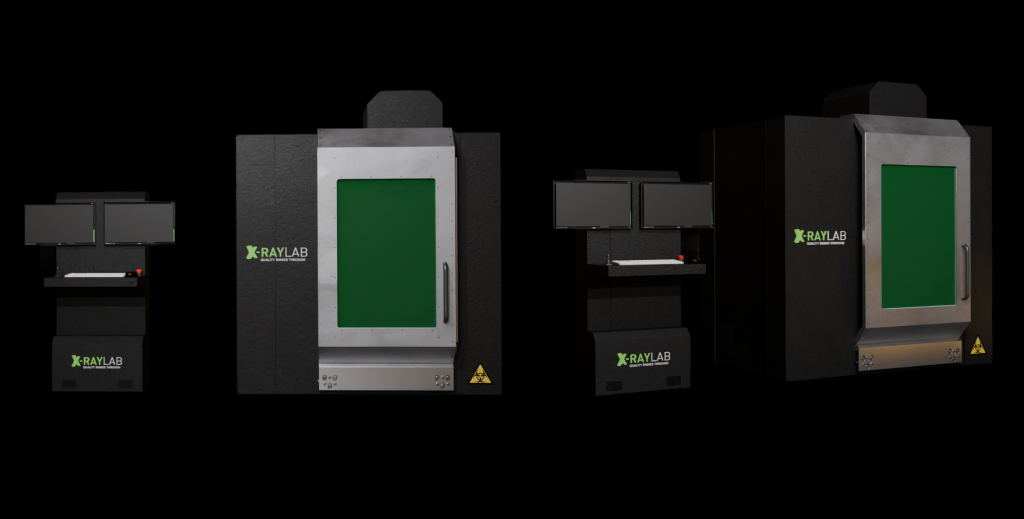

225 kV 2D / 2.5D-System (fOptional CT) — For Heavy Castings & Large Parts

When You Need More Power

Use this model for aluminum and steel castings, ceramics, composites, weld inspection, and large parts that require deeper penetration.

Feature Overview

- Penetration: ~150 mm (Al), ~25 mm (Fe)

- Detection volume: Ø 1,200 mm × 1,200 mm

- Max load: 300 kg

- Enhanced imaging software: filtering, stacking, 3D slicing, measurements, shading, annotations

Dimensions & System Specs

- Footprint: 3,200 × 3,873 × 3,277 mm

- Weight: 8,500 kg

- Power Requirements: 5-wire AC 380 V, max 9.0 kW

- Tube: 225 kV, dual power up to 1,800 W, focal spots 0.4 / 1.0 mm

- Detector: 250 × 300 mm, 139 µm resolution

- Safety & Design: Motorized lift-out mechanisms, anti-folding lead doors, protective grounding, voltage regulation

Packaging

- X-ray module crate: 3,700 × 2,760 × 2,590 mm

- Operator console crate: 1,400 × 1,070 × 1,500 mm

- Total shipping weight ~9,000 kg

225 kV X-Ray System (2D / 2.5D Optional CT)

245–300 kV Micro-Focus CT System — For 3D Imaging & Advanced R&D

For Cutting-Edge 3D Inspection

This system enables computed tomography (CT) scanning, letting you see inside objects in full three dimensions. Perfect for battery packs, composite assemblies, fiber analysis, structural parts, and e-mobility applications.

What Makes It Stand Out

- PolyCT ready: Supports multi-axis CT scanning with speed boost

- Optional second tube & additional line detector for advanced configurations

- Max sample size: 750 × 800 mm

- Max load: 30 kg

- Operates at 245–300 kV; optional 180 kV transmission tube

- HD detector: 426 × 426 mm

- X-ray Emission: < 2.5 µSv/h

Dimensions & System Specs

- Overall size: 2,800 × 1,700 × 2,200 mm

- Weight: ≤ 5,000 kg

- Power Requirements: Five-wire AC 380 V, about 9.0 kW

Applications

- Shrinkage and void analysis

- Wall thickness measurement

- Fiber composite and delamination inspection

- Metrological CT measurement

- Batteries, structural assemblies, ceramics

245–300 kV Micro-Focus CT System

Comparing the Portfolio: Which System Fits Your Needs?

Your Requirement | Recommended Model(s) |

Microelectronics / PCBs | 130 kV 2D/2.5D System |

Medium castings & components | 160 kV System |

Large castings & structural parts | 225 kV System |

3D CT imaging / R&D | 245–300 kV Micro-Focus CT |

Each model is designed with safety, usability, and scalability in mind. Whether your priority is micro-level defect detection or large-part volumetric analysis, XRAY-LAB has the right tool.

Conclusion

Industrial progress depends on precision, safety, and reliability. At XRAY-LAB, our range of high-resolution X-ray Lab inspection systems ensures that manufacturers across electronics, automotive, aerospace, and energy sectors can meet the highest standards of quality assurance. From compact 130 kV X-ray systems to powerful 300 kV CT scanners, every solution is engineered to reveal hidden defects and secure long-term product performance.

Whether you need micro-level accuracy or large-scale casting analysis, our systems provide the clarity, control, and confidence you require. Explore the right model for your application and take the next step toward smarter, safer, and more efficient production.

Get connected with XRAY-LAB today — where invisible flaws meet visible solutions.