Introduction

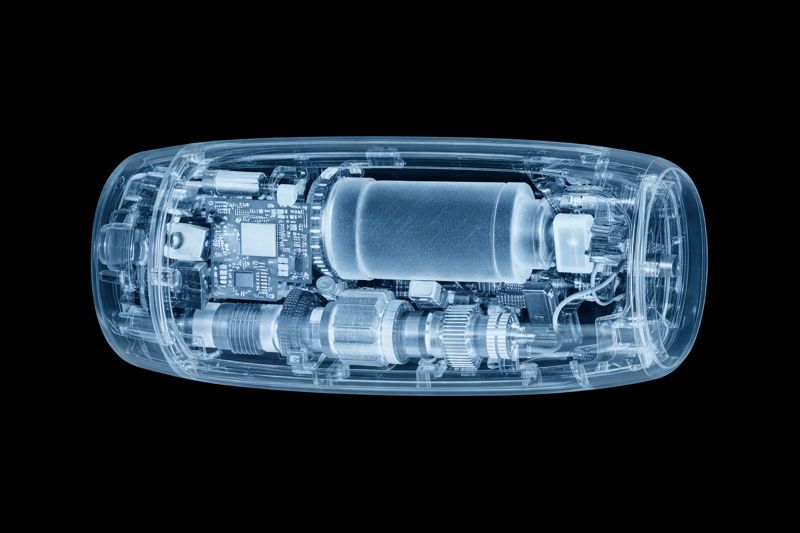

X-ray inspection of sealed assemblies and enclosures has become an essential quality assurance method for components that cannot be opened without destruction. Modern products across electronics, automotive systems, industrial machinery, and aerospace rely on sealed housings and encapsulated assemblies to protect sensitive internals from environmental and mechanical exposure.

Once sealed, internal verification becomes impossible using conventional inspection techniques. X-ray imaging provides a non-destructive pathway to examine internal structures, validate assembly accuracy, and detect hidden defects while maintaining complete enclosure integrity.

Xray Lab delivers advanced X-ray and CT inspection services designed to evaluate sealed and encapsulated components with precision, supporting reliability in high-performance applications.

Table of Contents

X-ray inspection reveals internal structures within fully sealed electronic enclosures

The Inspection Challenge of Fully Sealed Assemblies

Sealed enclosures are intentionally designed to prevent access. Adhesives, welding, potting compounds, and overmolding processes create robust barriers that safeguard internal components but also eliminate post-assembly visibility.

Without X-ray inspection, internal issues such as misaligned components, incomplete connections, internal damage, or foreign material may remain undetected until failure occurs in service. For assemblies operating in safety-critical or high-value environments, this risk is unacceptable.

X-ray inspection overcomes these limitations by penetrating enclosure materials and revealing internal geometry without disturbing seals or protective layers.

Internal Defects Identified Through X-Ray Imaging

X-ray inspection exposes a wide range of internal conditions within sealed assemblies:

Encapsulation voids can be detected within potting materials that may compromise thermal management or mechanical stability.

Misaligned or displaced components become visible inside closed housings, particularly after vibration or thermal cycling.

Hidden fractures, broken conductors, or incomplete internal connections can be identified before functional failure occurs.

Foreign objects or material inconsistencies introduced during assembly are clearly revealed through contrast differences in X-ray images.

These insights enable corrective action long before components reach operational environments.

Advanced X-Ray and CT Techniques for Sealed Components

Two-dimensional X-ray inspection provides rapid internal visibility, making it ideal for identifying gross defects, alignment issues, and internal damage within sealed casings. This technique is commonly used for inline or batch inspection where speed and efficiency are critical.

Computed Tomography (CT) inspection extends this capability by generating a full three-dimensional reconstruction of the sealed assembly. CT scanning allows precise measurement of internal features, verification of clearances, evaluation of material distribution, and detailed defect characterization.

Inspection data is further processed using advanced analysis software, producing high-resolution visualizations and structured reports that support quality assurance, root-cause analysis, and regulatory documentation.

Value of X-Ray Inspection for Sealed Enclosures

X-ray inspection eliminates the need for destructive disassembly while delivering complete internal visibility. This approach significantly reduces scrap rates, prevents costly rework, and protects product integrity.

By identifying internal defects early, manufacturers reduce the risk of field failures, warranty claims, and safety incidents. Verification of internal assembly accuracy also strengthens confidence in long-term performance under demanding operational conditions.

Xray Lab supports these outcomes by combining high-resolution imaging systems with expert interpretation, ensuring sealed assemblies meet stringent quality and reliability expectations.

Frequently Asked Questions

Which sealed assemblies are suitable for X-ray inspection?

Sealed electronic enclosures, encapsulated modules, industrial casings, battery assemblies, and sensor housings can be inspected without opening.

Can X-ray imaging penetrate potting and overmolding materials?

Most potting compounds, resins, and polymers can be effectively penetrated using optimized X-ray and CT inspection parameters.

What advantages does CT scanning offer for sealed assemblies?

CT scanning delivers full 3D visualization, enabling accurate localization, measurement, and analysis of internal features and defects.

Does X-ray inspection affect the functionality of sealed components?

When properly applied, X-ray inspection is non-destructive and does not alter component performance or integrity.

How does Xray Lab ensure reliable inspection results?

Xray Lab utilizes advanced imaging systems, optimized inspection techniques, and expert analysis to deliver accurate, application-specific results.