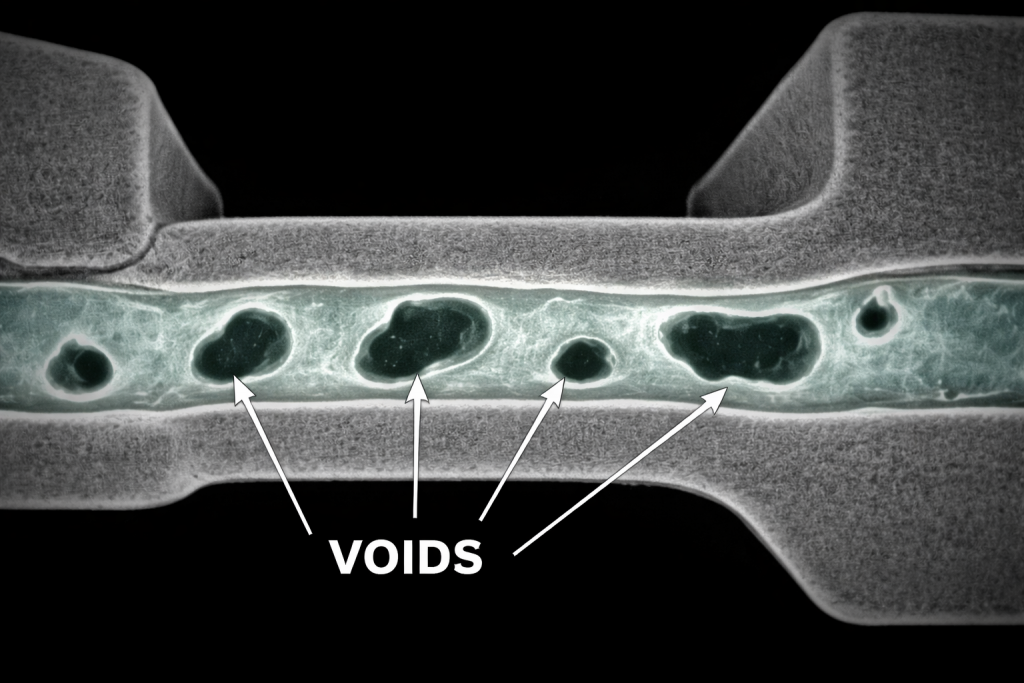

Adhesive bonding has become a standard joining method in modern manufacturing, particularly for multi-material assemblies combining metals, plastics, and composites. Ensuring the quality of these bonds is critical for structural integrity, product reliability, and safety. However, internal defects such as voids, incomplete adhesive coverage, or delamination are often invisible to the naked eye.

Non-Destructive Testing (NDT) using X-ray and CT inspection provides a reliable solution for evaluating adhesive bonds without compromising the assembly.

X-RAYLAB, a leading provider of NDT services in the USA, specializes in high-resolution X-ray and CT inspection to verify bond quality, detect voids, and map adhesive distribution for industrial and technical assemblies.

Table of Contents

X-ray inspection detects hidden voids in adhesive layers of bonded assemblies.

Why Adhesive Bond Inspection is Essential

Multi-material assemblies rely on adhesive bonds to transfer loads, maintain alignment, and resist environmental stresses. Even minor defects in bonding can reduce mechanical strength, cause premature failure, or compromise safety.

Traditional inspection methods cannot access the internal bond interface without destroying the assembly. X-ray and CT inspection overcome this limitation by providing a clear internal view, enabling manufacturers to:

- Verify uniform adhesive coverage

- Detect voids or trapped air pockets

- Identify delamination or weak bond areas

- Ensure consistent bond quality across batches

Common Defects Detected in Adhesive Bonds

- Void Formation – Air pockets or gaps within the adhesive layer reduce bond strength.

- Incomplete Coverage – Areas where adhesive has not fully spread can lead to stress concentration points.

- Delamination – Separation between bonded surfaces can compromise structural integrity.

- Contamination – Particles or residues trapped within the bond may weaken adhesion.

X-Ray and CT Inspection Process

- 2D X-Ray Imaging – Provides a quick internal overview of adhesive layers, highlighting voids, misalignment, or coverage issues.

- CT Scanning – Offers a volumetric representation of bonded interfaces, allowing detailed analysis of adhesive thickness, void distribution, and interface quality.

- Analysis & Reporting – Software tools process the inspection data to quantify defects, map adhesive coverage, and generate detailed reports for quality assurance and certification.

Advantages of NDT for Adhesive Bonded Assemblies

- Ensures structural integrity without disassembly or destructive testing

- Detects internal defects that could lead to mechanical failure

- Supports regulatory compliance and product certification in the USA

- Reduces scrap, rework, and warranty claims

- Provides confidence in multi-material assembly performance

X-RAYLAB delivers precise NDT services across the USA, ensuring that adhesive bonded assemblies meet the highest quality standards and reliability requirements.

Frequently Asked Questions

Which assemblies benefit from adhesive bond inspection?

Multi-material assemblies including metals, plastics, composites, and hybrid structures, benefit from this inspection.

Can X-ray detect voids in adhesive layers?

Yes, both X-ray and CT scanning can reveal voids, gaps, and incomplete coverage in the bond interface.

How does CT scanning improve adhesive bond inspection?

CT scanning generates a 3D model of the adhesive layer, allowing precise measurement of thickness and defect localization.

Is NDT safe for delicate bonded assemblies?

Yes, X-ray and CT inspection are non-destructive and do not compromise bond integrity.

Why choose X-RAYLAB for NDT services in the USA?

X-RAYLAB combines advanced imaging technology with expert analysis to deliver reliable, actionable insights for adhesive bonded assemblies.