Why Industrial CT scan Is a Game-Changer for Manufacturers?

Accuracy and standards of excellence are critical in today’s manufacturing industry, and industrial CT scanning offers both. CT imaging’s remarkable 3D imaging capability using X-ray tech enables the inspection of parts without the need for deconstruction.

Compared to traditional inspection methods, industrial CT scans are far more superior since they can identify hidden errors and features. This guide explains the industrial CT scanning process, its benefits, and its increasing use among forward-looking manufacturers undergoing digital transformations.

Table of Contents

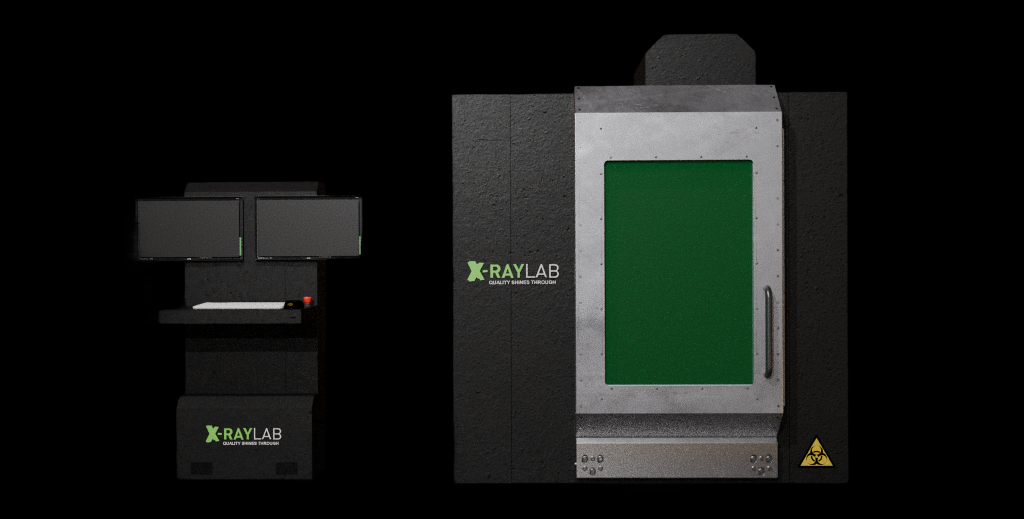

Industrial CT scanning system with dual-monitor control setup — enabling precise 3D X-ray inspection for manufacturing quality assurance.

What Is an Industrial CT scan? How It Works and Why It Matters?

An Industrial CT scan functions by taking a component and spinning it while projecting X-ray beams at it. The X-ray beams are collected by detectors which convert these X-ray beams into 2D slices. Sophisticated methods can be used to convert these 2D slices into 3D geometric models which show the surface and volume.

Key Components:

- X-ray source: Emits high-energy radiation.

- Detector: Captures transmitted rays.

- Turntable: Rotates the part for 360° coverage.

- Software: Builds 3D volume and analysis tools.

Unlike methods such as ultrasound or surface measurements, traditional NDT techniques do not examine internal voids, cracks, imperfections, or discrepancies in wall thickness. CT scanning, on the other hand, captures every internal or external detail.

Image: An imaging computer aided with software a labelled interface demonstrates elements such as the x-ray emission point, x-ray sensor, the revolving component, as well as the software interphase.

This concise video covers everything you need to know: https://www.youtube.com/watch?v=conT-PhxJ78

Applications of Industrial CT Scanning in Manufacturing

The application of CT scanning is no longer confined to the medical and aerospace fields. Now, it’s utilized in multiple industries:

Industry | Application | Benefit |

Aerospace | Blade crack inspection | Improves flight safety |

Automotive | EV battery pack scanning | Reduces fire risk and failure rates |

Consumer Electronics | PCB and solder joint verification | Enhances product reliability |

Medical Devices | Implant and catheter wall thickness checks | Ensures FDA compliance |

Plastics & Injection Molding | Shrinkage, warpage, and void detection | Minimizes material waste and rework |

Why Manufacturers Choose Industrial CT Scan for QA and R&D?

An industrial CT scan provides a one-stop solution for different engineering activities alongside:

- Dimensional analysis: Measure internal features without cutting the part.

- Reverse engineering: Generate CAD models from complex or legacy components.

- Failure analysis: Locate internal cracks, porosity, or material shifts.

- Supplier qualification: Objectively assess part quality from external vendors.

It surpasses traditional approaches such as calipers and CMMs in handling intricate shapes and diminutive components, particularly with scan resolutions reaching microns.

Industrial CT Scan vs Traditional Testing Methods

Method | Destructive? | Internal View? | Speed | Accuracy |

CMM | No | No | Medium | High (external) |

Ultrasound | Yes / No | Partial | Fast | Medium |

X-ray radiography | No | 2D only | Fast | High |

CT Scan | Yes | Yes (3D) | Moderate–Fast | Very High |

Considerations Before Adopting Industrial CT Scanning

If you’re thinking about implementing CT in your operations, here’s what to consider:

- Part material: Metals require higher energy X-rays; polymers scan easily.

- Size: Larger parts need specialized CT systems.

- Resolution needs: Higher resolution = more scan time and cost.

- Throughput: High-volume scanning? Look for automation-ready systems.

- Cost: Industrial CT scanners range from $100k to $1M+. Outsourcing is often a smart start.

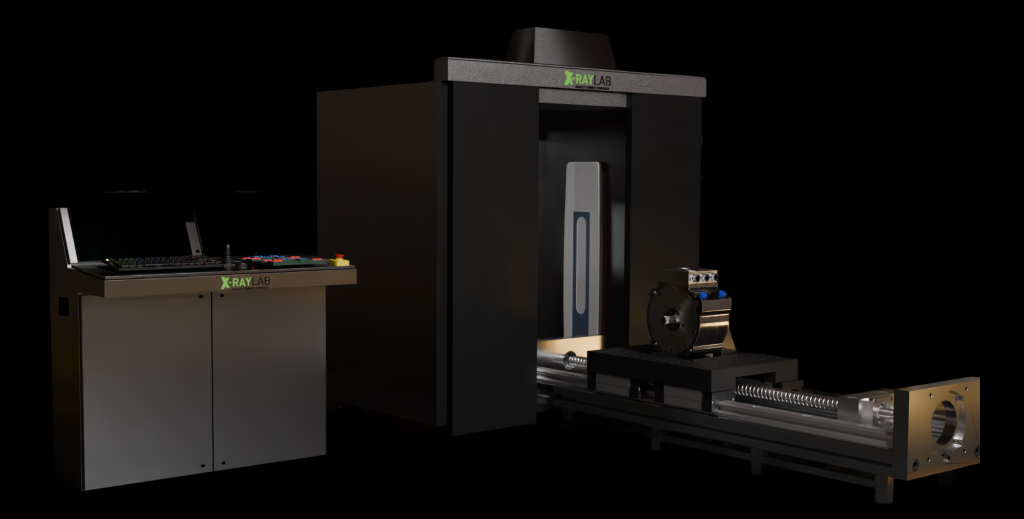

High-power industrial CT scanner designed for large components such as aerospace blades, automotive castings, and EV battery modules.

Conclusion

An industrial CT scan is no longer just about seeing inside a part. It’s about transforming how manufacturers design, validate, and deliver their products. From detecting invisible flaws to enabling full digital traceability, CT scanning offers a return on precision, speed, and trust. Whether you’re in aerospace, medtech, automotive, or consumer goods, now’s the time to see industrial CT as not just a tool, but a competitive advantage.

Xray-Lab provides advanced industrial CT scanning for non-destructive quality inspection. We help manufacturers detect internal defects, verify tolerances, and ensure component integrity with micron-level precision. Our CT solutions reduce rework, support traceability, and elevate QA standards. Learn more or contact us to optimize your inspection process.

Frequently Asked Questions

What Makes Industrial CT Scanning Better Than Traditional Inspection Methods?

Industrial computed tomography delivers a comprehensive three-dimensional image without damaging a part. In contrast to coordinate measuring machines and traditional X-ray techniques, CT reveals delicate internal features, such as micro-cracks, porosity patterns, and subtle changes in wall thickness, in a single exposure. This capability streamlines quality control and enhances failure investigation.

Can Industrial CT Scanning Be Used for Plastic and Metal Parts?

Yes. CT scanning accommodates both polymers and metals. Denser metals demand higher-energy X-ray sources to penetrate, whereas plastics and composites generally provide quicker, simpler scans. The specific material influences the selection of scanner settings, ensuring optimal image quality and efficiency.

Is CT Scanning Only Suitable for R&D, or Can It Be Used in Production?

CT scanning serves both research and high-volume production environments. In R&D, technology serves as the standard for prototyping and verifying designs, while production applications are growing, particularly when paired with automated handlers for inline inspection and managing the quality of incoming components from suppliers.

How accurate is industrial CT scanning for dimensional measurement?

With resolution down to the micron scale, CT scanning surpasses conventional gauges for complex shapes, concealed recesses, and internal features that calipers and coordinate-measuring machines cannot directly interrogate.

What Are the Limitations or Challenges of Industrial CT Scanning?

Speed of scanning, capital expense, and the physical size of components are the principal hurdles. High-resolution datasets naturally extend inspection duration and demand more advanced and costly hardware. For oversized or high-density items, delegating the scanning to a commercial CT laboratory frequently proves the most economical choice.