The PolyCT series represents a new generation of modular upgrade kits that enhance the efficiency, precision, and versatility of computed tomography (CT) systems by up to fivefold. Designed for seamless integration with nearly all CT scanners on the market, PolyCT enables higher throughput when inspecting hard-to-penetrate samples, without compromising image quality or workflow performance. The maintenance and wear-and-tear costs of the CT system decrease significantly. The purchase of new CT systems to increase capacity is no longer necessary.

Table of Contents

Product Line Overview

The PolyCT series is a modular solution designed for end users and manufacturers seeking greater inspection capacity, flexibility, and performance. Each model offers significant advantages depending on sample size, number of axes, throughput requirements, and inspection complexity.

POLYCT–M3

A compact triple-axis module ideal for small to medium-sized components. The M3 model is perfect for laboratories aiming to boost throughput without altering their existing CT setup. It enables fast installation, precise alignment, and repeatable accuracy—ideal for inspecting small, hard-to-penetrate parts.

POLYCT–L3

The L3 variant was developed for larger and heavier samples. The L3 is commonly used in the aerospace, automotive, and advanced manufacturing industries, offering the same high precision and mechanical stability as the M3, but designed for handling larger samples.

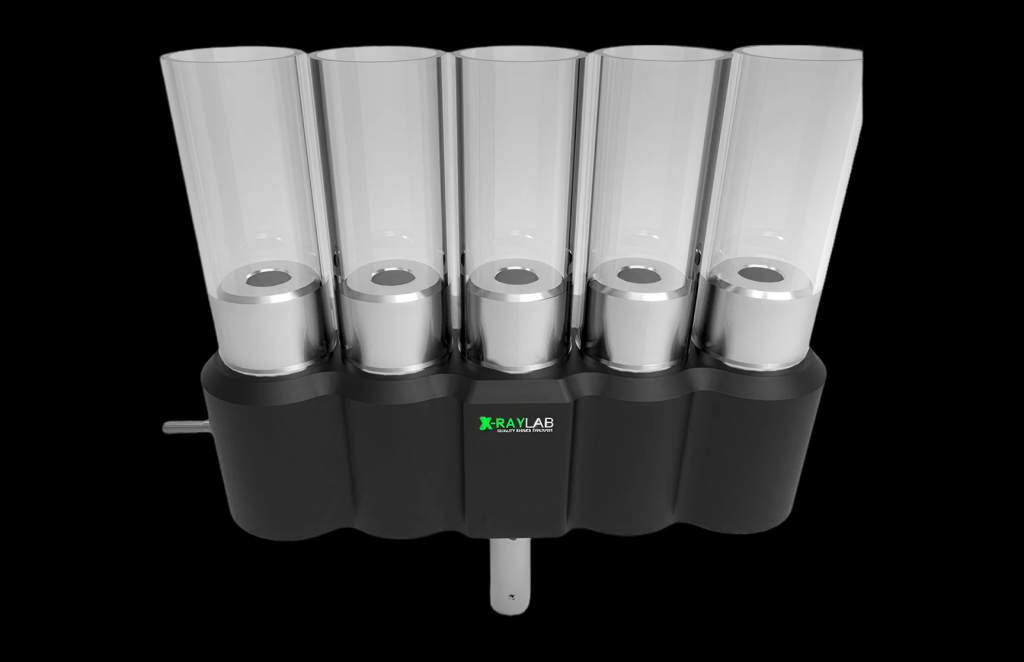

POLYCT–M5

The most advanced model in the series, POLYCT–M5 features five independent rotation axes, enabling simultaneous scanning of multiple samples. This configuration is ideal for high-throughput production environments or research setups requiring efficient multi-sample testing. Despite processing multiple parts, the image fidelity remains almost the same as with single-sample scans.

POLYCT–BUNDLE

A complete, ready-to-use solution that includes the PolyCT module, PolyReko reconstruction software, and essential mounting accessories. The bundle covers a wide range of requirements, offering full compatibility with existing CT systems and immediate productivity gains, ideal for laboratory and production environments.

No changes to existing hardware or software are required.

POLYCT–CUSTOM

For organizations with unique inspection challenges, the Custom configuration provides a tailor-made approach. Options include adjustments to the number of rotation axes, sample holder geometry, automation features, or system footprint. This flexibility makes it suitable for specialized research or industrial applications that demand bespoke CT configurations.

Key Features and Advantages

Feature | Description & Benefit |

Universal Compatibility | Works with nearly all CT systems currently available on the market—no need for a complete system replacement. |

Quick Setup | Can be put into operation quickly and easily, minimizing downtime and setup effort. |

Passive Central Rotation Axis Design | Enables permanent installation without affecting CT functionality or measurement precision. |

Integrated Laser Cross (Class A) | Simplifies alignment of the module along the beam axis for accurate setup and repeatability. |

Universally Usable Specimen Holders | Supports diverse sample sizes and geometries for flexible usage. |

Optimized Detector Utilization | Allows simultaneous multi-part scanning while maintaining high image quality. |

Closed Process Chain | Integrates hardware and software for a seamless, automated workflow. |

High Reliability and Image Quality | Delivers consistent results with image fidelity comparable to single-part scans. |

Scan Speed | Can be reduced by a multiple, depending on the number of axes. |

Wear and Tear | Reduced system wear due to the increased number of parts that can be scanned together. |

Resolution | A 4K detector can be used optimally, as the resolution is distributed across multiple rotation centers. This reduces the number of projections required. |

Performance Highlights

PolyCT systems are engineered to deliver measurable productivity improvements. By enabling simultaneous scanning of multiple components, PolyCT significantly reduces scan times per part. The multi-axis design ensures each sample has its own rotation center—eliminating elongated projection artifacts often found in conventional multi-object scanning setups. Mechanical precision tests show measurement deviations below 10 µm, confirming the system’s remarkable stability. Even at higher object offsets, PolyCT maintains negligible signal-to-noise loss, ensuring reliable and accurate results across every scan.

To explore the complete range of specifications and model comparisons, visit the official PolyCT Product Overview page for in-depth technical insights.

Software Integration

Each PolyCT system is complemented by PolyReko, a dedicated reconstruction software that automates CT data processing. The software supports industry-standard formats, including Fraunhofer EZRT (.rek) and VGStudioMax (.vgl), ensuring compatibility with existing analysis tools. PolyReko creates a closed process chain from scanning to reconstruction, minimizing user interaction and improving workflow continuity. Regular updates ensure compatibility with evolving CT technologies and data standards.

Use Cases

PolyCT is ideal for a wide range of applications that demand precision, efficiency, and scalability in CT inspection: Research and Development Laboratories looking to accelerate testing and data collection. Industrial Inspection Facilities conducting multi-part scanning with consistent quality. Manufacturers optimizing CT resources and reducing inspection cycle times. Quality Assurance Teams requiring repeatable results with minimal operator effort. By combining engineering precision with operational simplicity, PolyCT enables both engineers and decision-makers to achieve measurable gains in productivity and quality assurance.

Customization Options

Every inspection setup has unique challenges. PolyCT’s Custom Configuration Service allows clients to modify axis count, sample holder design, automation level, and system layout to match their operational goals. This ensures seamless integration into research labs, CT facilities, or automated inspection lines.

Conclusion

PolyCT offers a versatile, high-precision solution for laboratories and manufacturers seeking to optimize CT inspection workflows. From small-scale component testing with the M3 to high-throughput multi-sample scanning with the M5, the PolyCT series adapts to a wide range of industrial and research applications. With its intuitive setup, universal compatibility, and advanced software integration, PolyCT helps organizations maximize efficiency without compromising quality.

Xray Lab recommends PolyCT as a reliable solution for enhancing productivity and achieving consistent, high-quality CT results across diverse inspection environments.