Hybrid assemblies combining metals, plastics, and composites are increasingly common in automotive, aerospace, and electronics applications. These multi-material structures offer exceptional strength-to-weight ratios, durability, and functionality, but the interfaces between different materials can hide critical weaknesses. Poor bonding, voids, or delamination often remain undetected until a component fails under stress.

Non-Destructive Testing (NDT) provides a way to inspect these assemblies without disassembly. X-ray and CT inspections enable engineers to visualize internal interfaces, evaluate bonding quality, and detect hidden flaws before they compromise performance. X-RAYLAB, a leading NDT provider in the USA, specializes in delivering these high-resolution inspections for complex multi-material components.

Table of Contents

X-ray inspection reveals hidden voids and misalignments in hybrid assemblies

Understanding the Risks in Multi-Material Assemblies

The combination of metal, plastic, and composite layers introduces unique inspection challenges. Differences in density and material properties make traditional visual or surface inspections inadequate. Even minor defects at material interfaces, such as a tiny void or misaligned layer, can impact structural integrity, load transfer, and long-term durability.

Adhesive layers, mechanical joints, or co-molded interfaces must be flawless. Any inconsistencies can lead to localized stress points, delamination, or failure under operational loads. Detecting these internal issues early is crucial to prevent costly recalls or safety incidents.

How X-Ray and CT Inspection Reveal Hidden Defects

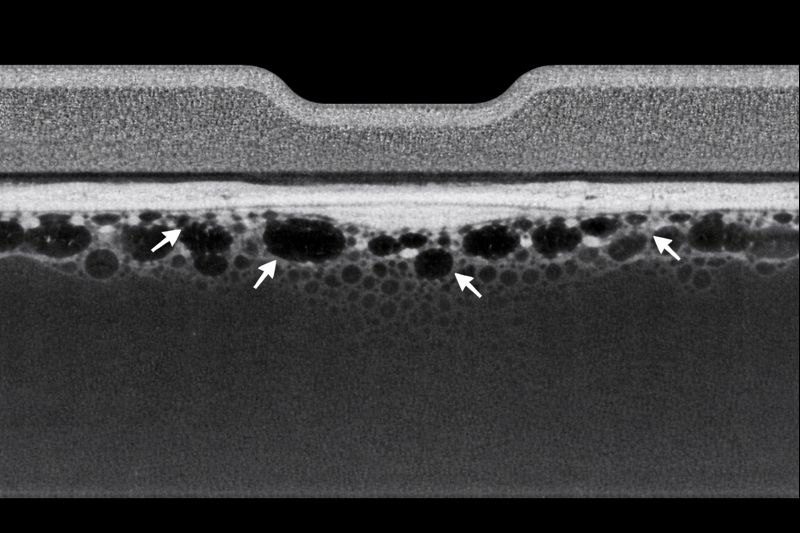

X-ray imaging produces clear two-dimensional views of multi-material assemblies, highlighting density variations, misalignments, and internal inclusions. This allows manufacturers to quickly detect major defects that could affect functionality.

For more detailed assessment, CT scanning provides a full three-dimensional reconstruction of the assembly. This volumetric view enables precise inspection of interfaces, adhesive layers, and hidden voids. Advanced software can quantify defects, measure their location and size, and generate detailed reports for quality control, regulatory compliance, and production optimization.

Advantages of NDT for Multi-Material Assemblies

Adopting X-ray and CT inspection provides numerous benefits. Manufacturers can detect defects early, verify bonding integrity, and ensure consistency across production batches. In the USA, X-RAYLAB’s NDT services help engineers optimize hybrid designs for durability, safety, and performance, reducing the risk of rework, warranty claims, and operational failures.

By providing insight into the internal structure of multi-material assemblies, NDT empowers manufacturers to deliver products that meet both regulatory standards and customer expectations for reliability.

Frequently Asked Questions

How are internal defects detected in hybrid assemblies?

X-ray and CT inspection penetrate multiple materials to visualize hidden flaws, including voids, delamination, and bonding inconsistencies, without disassembly.

Why is interface inspection important?

Interfaces often represent the weakest points in hybrid components. Early detection of flaws ensures proper load transfer and prevents premature failure.

Can bonding quality be assessed with X-ray alone?

X-ray is effective for identifying gross defects and density variations, while CT scanning provides a 3D view to evaluate adhesive distribution and interface integrity in detail.

Is NDT safe for sensitive or high-value assemblies?

Yes, X-ray and CT inspections are non-destructive, preserving the structural and functional integrity of the assembly.

Why choose X-RAYLAB for multi-material NDT in the USA?

X-RAYLAB combines advanced imaging technology with expert analysis to deliver actionable insights, ensuring hybrid assemblies meet strict quality and reliability standards.