Non-Destructive Testing (NDT) for sintered metal parts is crucial in high-load applications where structural integrity is non-negotiable. X-ray and CT inspections are used to detect density variations, internal cracks, and porosity that can compromise performance in automotive components, heavy machinery, and industrial equipment.

X-RAYLAB provides advanced CT scanning and X-ray inspection services to ensure sintered metal components meet the highest quality and safety standards, minimizing failure risks in critical applications.

Table of Contents

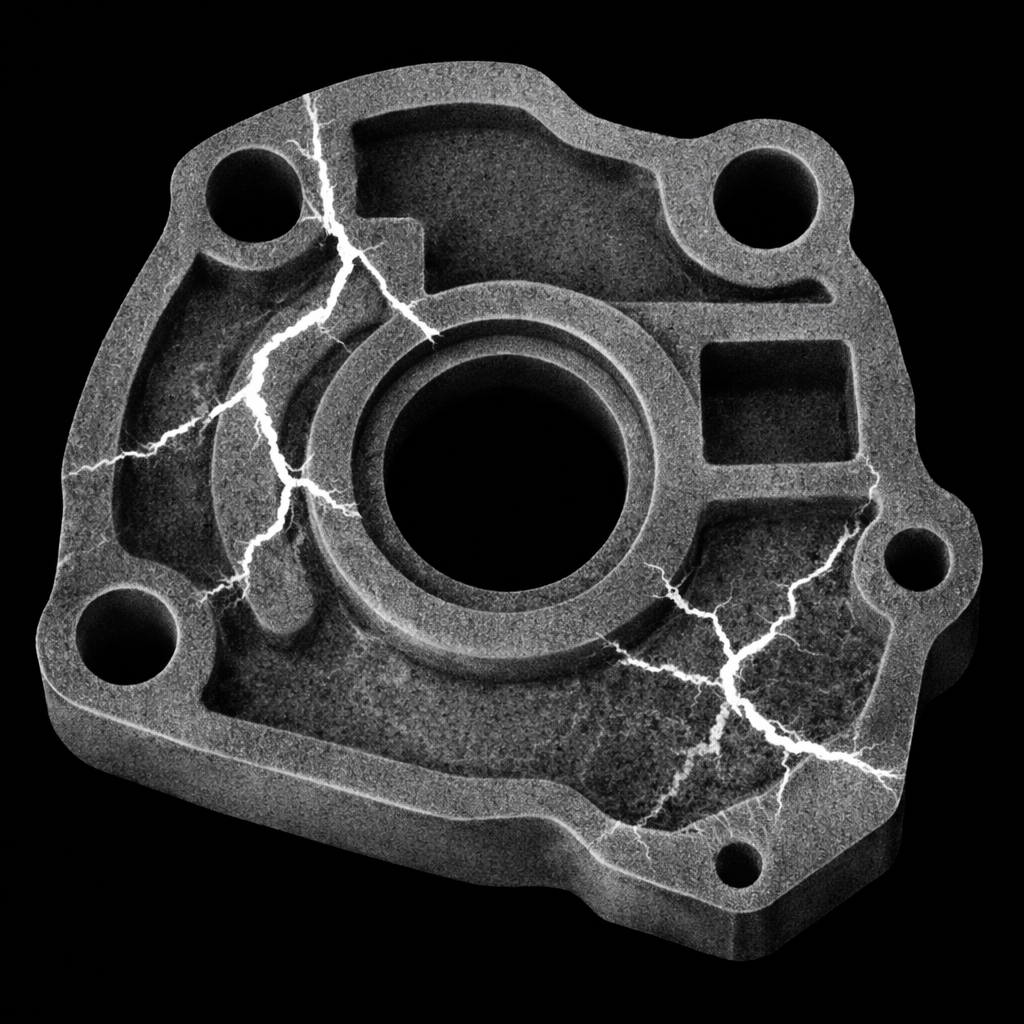

X-ray inspection highlights internal cracks and inclusions for quality assurance.

Importance of NDT in Sintered Metal Components

Sintered metals are prone to microstructural defects like voids, inclusions, and uneven density. NDT techniques, especially X-ray and computed tomography (CT), allow for precise evaluation without damaging the part. Detecting these defects early prevents costly downtime, ensures reliability, and supports compliance with industry standards.

Common Defects in Sintered Metal Parts

- Porosity – Small voids or air pockets within the metal structure reduce mechanical strength and act as initiation points for cracks under high stress.

- Internal Cracks – Micro-cracks may develop during sintering or under operational load, potentially propagating over time and causing premature failure.

- Density Variations – Uneven material density creates localized stress concentrations, reducing overall durability and load-bearing capacity.

- Inclusions – Foreign particles, such as oxides or residual powders, trapped during sintering, compromise material integrity and reduce fatigue resistance.

X-ray and CT Inspection Process

- X-ray Inspection – Provides a 2D overview of internal structures, highlighting cracks, inclusions, and gross porosity patterns for quick identification of major defects.

- CT Scanning – Offers detailed 3D imaging, enabling detection of subtle porosity, density variations, and hidden micro-cracks, allowing precise quantification of defects.

- Analysis & Reporting – Advanced software evaluates detected anomalies, generating detailed inspection reports that support quality control, process improvements, and certification compliance.

Advantages of NDT for High-Load Applications

- Prevents catastrophic failures – Ensures automotive and industrial machinery components operate safely under extreme loads.

- Reduces waste and rework – Early detection of defects prevents manufacturing losses and increases overall efficiency.

- Supports regulatory compliance – Meets industry standards and certification requirements for high-performance components.

- Enhances confidence in performance – Validates material reliability, helping manufacturers ensure parts maintain strength and durability under operational stress.

X-RAYLAB ensures each sintered metal component undergoes thorough inspection using cutting-edge X-ray and CT technology, providing actionable insights that enhance product quality, reduce risk, and extend service life.

Frequently Asked Questions

What types of defects can NDT detect in sintered metal parts?

NDT identifies internal cracks, porosity, density variations, and inclusions that may compromise performance.

How does CT scanning differ from standard X-ray inspection?

CT scanning provides 3D imaging for precise defect measurement, while standard X-rays offer 2D views of internal structures.

Why is NDT critical for high-load applications?

High-load parts experience extreme stress; undetected defects can lead to failure, downtime, or safety hazards.

Can NDT be performed on finished sintered components?

Yes, NDT is non-destructive, allowing full inspection without affecting the part’s integrity.

How does X-RAYLAB ensure accurate inspection results?

X-RAYLAB uses advanced CT and X-ray systems with expert analysis, producing detailed reports for quality assurance and compliance.