Composite materials are widely used in aerospace, automotive, energy, and other high-performance industries because they are lightweight yet strong. However, even the strongest composites can have hidden flaws like cracks, delamination, or voids that weaken the structure. Non‑destructive testing (NDT) allows these defects to be detected without damaging the material.

Table of Contents

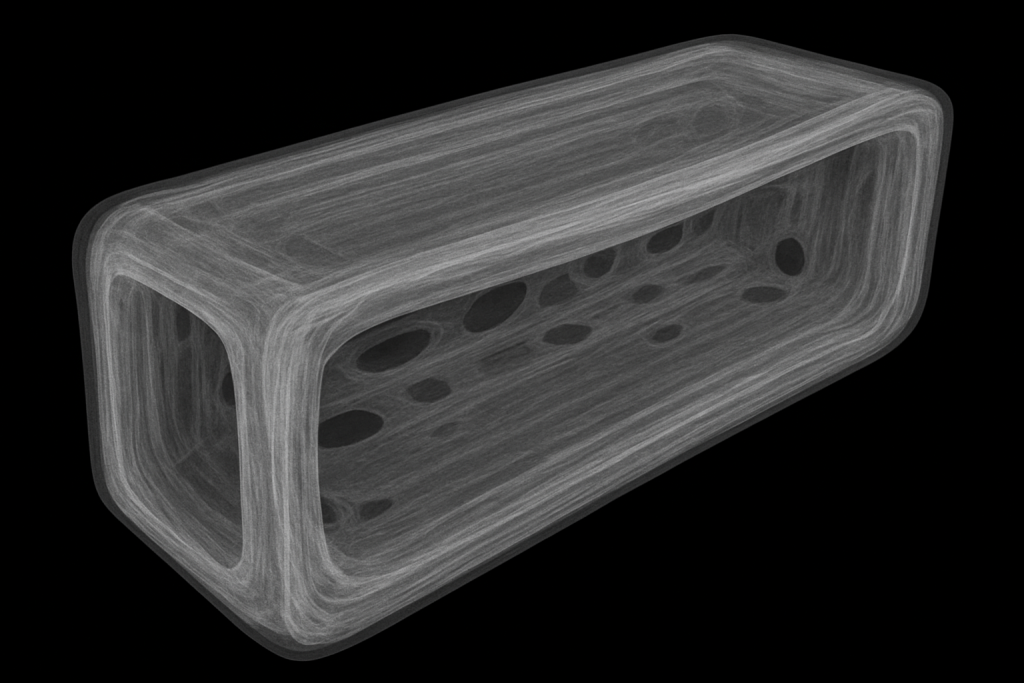

3D X-ray CT scan of a composite structure revealing internal layers and voids that are invisible to surface inspection.

Common Defects in Composite Materials

Composite materials can develop several types of hidden problems, including:

- Delamination and Debonding – Layers separating from each other or from the core.

- Voids or Air Pockets – Small empty spaces inside the material that reduce strength.

- Cracks or Fiber Damage – Tiny fractures that may grow over time.

- Impact Damage – Hidden damage from bumps or collisions.

- Fiber Misalignment or Uneven Resin – Irregularities in fiber orientation or resin distribution affecting performance.

Because these defects are often inside the material, simple visual checks are not enough. Advanced NDT techniques are needed to reveal them.

How NDT Detects Hidden Flaws

There are several NDT methods that work well with composites:

- Visual Inspection – The first step in NDT, used to identify surface defects such as scratches, wrinkles, or visible cracks.

- Ultrasonic Testing – Uses high-frequency sound waves to detect internal defects such as delamination, cracks, or voids, and can generate detailed structural maps.

- X‑ray and CT Scanning – Allows visualization of internal features, identifying hidden voids, uneven fiber distribution, or internal cracks.

- Thermal Imaging – Detects subsurface defects such as delamination or disbonds by analyzing heat flow through the material.

- Optical Techniques (e.g., Shearography) – Measures very small deformations in a material under stress, highlighting hidden flaws.

- Acoustic Emission Testing – Monitors a material in real time to detect cracks or fiber damage as it occurs.

Often, a combination of these NDT methods is employed to obtain a comprehensive assessment of a material’s condition. For instance, visual inspection and thermal imaging can identify potential problem areas, which can then be examined in greater detail using ultrasonic testing or X-ray/CT scanning.

Why Composites Are Challenging to Inspect

Unlike metals, composites are made of layers of fibers and resin, sometimes with cores or honeycomb structures. This makes them strong but also tricky to inspect. Defects can be hidden deep inside, and different layers can affect how sound or heat moves through the material. That’s why advanced NDT techniques are essential for accurate results.

At Xray Lab, we provide comprehensive NDT services for both welded components and composite materials. We assist manufacturers in detecting hidden defects to ensure that high-performance structures are safe, durable, and reliable. Whether during production, maintenance, or quality inspections, our team delivers accurate, non-destructive evaluations.

Frequently Asked Questions

What Are Common Defects in Composite Materials?

Delamination, voids, cracks, fiber misalignment, and impact damage are among the most common hidden defects in composite materials.

Which NDT Methods Are Best for Detecting Delamination?

Ultrasonic testing and thermal imaging are highly effective for detecting delamination. Optical techniques like shearography can also highlight potential areas of concern.

Can X ray or CT Scanning Detect Internal Flaws?

Yes, X‑ray and CT scans can reveal internal voids, uneven fiber distribution, and cracks that are not visible externally.

What Are the Limits of Thermal Imaging?

Thermal imaging is effective for detecting shallow or near-surface defects, but it may miss deep defects in thick components. Environmental factors, such as ambient temperature and airflow, can also affect results.

Why Use Multiple NDT Methods?

No single technique can detect all types of flaws. Combining different NDT methods provides a more comprehensive assessment and increases the likelihood of identifying hidden defects accurately.