Industrial CT has become an essential tool for manufacturers producing molded plastic components. As designs become more intricate—with thinner walls, internal ribs, snap-fits, and multi-material assemblies—traditional inspection methods often fail to capture hidden defects or subtle dimensional variations.

Industrial Computed Tomography (CT) enables complete 3D visualization of both internal and external structures without cutting the part. This makes it ideal for quality control, mold validation, and failure analysis across automotive, electronics, medical devices, and consumer product manufacturing.

Table of Contents

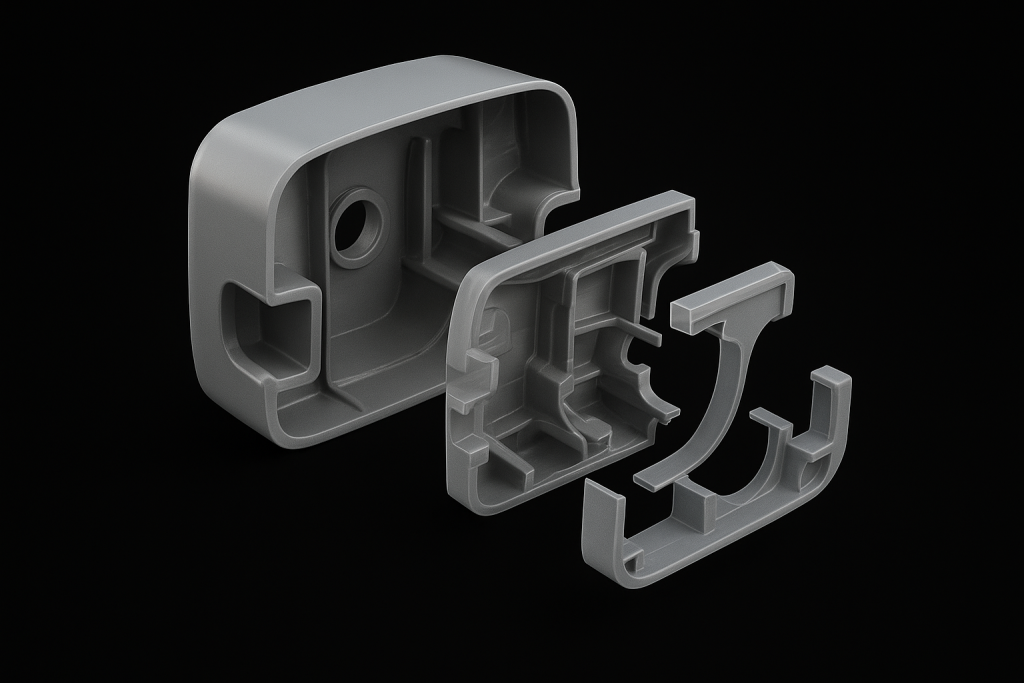

Combined CT cross-section and exploded 3D visualization showing the internal structure and hidden features of a molded plastic part.

Wall Thickness Analysis: Ensuring Structural Stability

Variations in wall thickness can affect part strength, cooling behavior, and long-term performance. Industrial CT provides full-volume wall thickness measurements, allowing engineers to detect:

- Thin or thick sections that deviate from the intended design

- Structural weaknesses in ribs, bosses, and snap-fit areas

- Production issues caused by uneven cooling or flow restrictions

Heat-map color visualizations make it easy to identify problem areas immediately, supporting mold adjustments and faster production refinement.

Detecting Voids, Porosity, and Internal Defects

Internal defects in plastic parts—such as voids, porosity clusters, or gas pockets—are difficult to identify using surface-based inspection tools. Industrial CT scanning detects these hidden flaws non-destructively and provides:

- High-contrast 3D renderings of voids and gas inclusions

- Quantitative analysis of porosity distribution

- Detection of short shots and incomplete filling

- Insights into weld lines and fiber-reinforced material behavior

This level of detail allows manufacturers to optimize process parameters and ensure long-term product reliability.

Warping and Dimensional Deviation Analysis

Warping is common in molded plastics due to material shrinkage, uneven cooling, or asymmetrical wall structures. Using Industrial CT, engineers can compare the scanned part against its CAD model to:

- Identify areas where deformation exceeds tolerance

- Visualize warping patterns through deviation color maps

- Make informed decisions about mold redesign or process corrections

This accelerates mold qualification cycles and improves first-pass yield during mass production.

Why Industrial CT Matters for Plastic Manufacturing

Industrial CT consolidates multiple inspection tasks—metrology, defect detection, and structural evaluation—into one non-destructive workflow. This reduces time, lowers scrap rates, and provides a higher level of confidence in the quality of molded plastic components.

X-ray Lab Services for Molded Plastic Part Inspection

XRAY-LAB offers advanced Industrial CT solutions designed for precision inspection of molded plastic parts. The company provides high-resolution CT scanning, detailed volumetric analysis, and customized evaluation processes for wall thickness, void detection, and warpage assessment.

With a strong global presence and experience across automotive, aerospace, electronics, and medical manufacturing, XRAY-LAB supports clients at every stage—from prototyping to full-scale production quality checks. More details are available on the company’s official website.

Frequently Asked Questions

What Is Industrial CT Scanning for Molded Plastic Parts?

Industrial CT scanning is a non-destructive testing (NDT) technique that uses X-rays to generate a detailed 3D model of a molded plastic part, capturing both its internal and external structures.

How Accurate Is Industrial CT for Wall Thickness Measurement?

Industrial CT provides micrometer-level precision and can measure thickness across complex and inaccessible areas.

Can Industrial CT Detect Internal Voids in Plastic Parts?

Yes. It identifies voids, gas pockets, porosity, and incomplete fills that are hidden from external inspection tools.

How Does CT Help Evaluate Warping?

CT data is compared with the CAD model, generating deviation maps that show how much the part has warped and where corrections are needed.

Is CT Scanning Suitable for Production-Level Quality Control?

Yes. CT supports first-article inspection, mold qualification, periodic audits, and process validation during mass production.