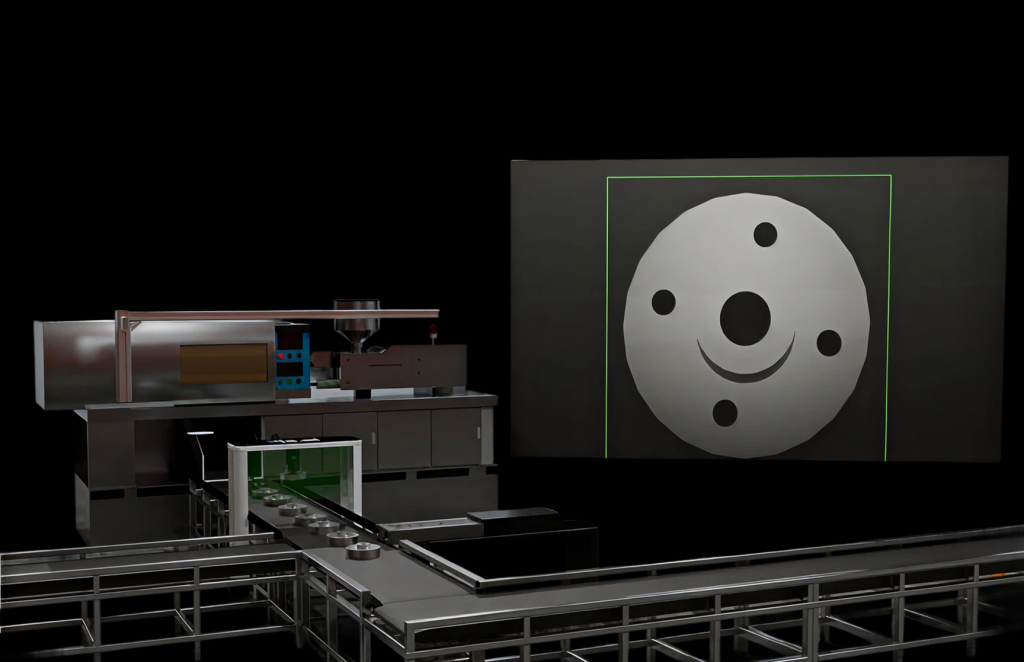

A new era of inspection and quality control is dawning, one in which automation, speed, and accuracy are not mutually exclusive but rather complementary advantages. A non-destructive technique for exposing the internal details of intricate components is industrial computed tomography (CT). Now, artificial intelligence (AI) is taking CT to a new level by providing industries like electronics and aerospace with intelligent automation, quicker workflows, and more precise defect detection.

A mainstay of non-destructive testing for a long time has been industrial CT. Engineers can examine internal defects, confirm dimensions, examine assemblies, and facilitate reverse engineering by using multiple X-ray projections to create high-resolution 3D models without causing any harm to the object.

However, industrial CT has historically balanced throughput and scan quality. Production feedback loops are slowed down by high-resolution imaging requirements for time-consuming scans and significant data reconstruction time.

Table of Contents

Industrial CT inspection enhanced by AI for precise defect detection and quality validation

AI Enters the Scene

That balance is being altered by artificial intelligence, especially deep learning. High-fidelity 3D volumes can now be produced from sparse or low-dose data using AI-enhanced reconstruction techniques, which significantly cut down on scan times without sacrificing image quality. AI is now being used in some commercial CT systems’ software pipelines to reduce artefacts, enhance details, and speed up imaging workflows in general.

AI is transforming the interpretation of CT data, going beyond image formation. Compared to human reviewers, AI-powered defect detection tools are significantly faster and more reliable at automatically identifying anomalies, even those that are subtle or hazy. AI simplifies point-cloud processing, enhances feature recognition, reduces noise, and more consistently aligns scan data with CAD models in dimensional metrology and reverse engineering applications.

AI models trained on CT-derived data help optimise process parameters, improve prediction accuracy, and enable real-time in-line adjustments in advanced manufacturing, especially additive processes.

Comparative View: Traditional CT vs. AI-Enhanced CT

Feature / Capability | Traditional CT | AI-Enhanced CT |

Scan Speed | High resolution requires longer scans | High resolution achievable with shorter scans |

Image Quality | Dependent on number of projections | Maintained or improved even with sparse data |

Defect Detection | Manual review prone to human error | Automated detection with high consistency |

Throughput | Limited by reconstruction time | Supports high-volume, inline inspections |

Process Adaptability | Static imaging workflow | Dynamic adjustments based on AI predictions |

Key Benefits of Combining Industrial CT with AI

- Faster Inspection Cycles: Near real-time analysis is made possible by AI, which speeds up reconstruction times.

- Better Image Quality: Even with sparse data, deep learning algorithms improve resolution, eliminate artefacts, and boost clarity.

- Automated Defect Detection: reliable, human-bias-free detection of inclusions, porosity, cracks, and other irregularities.

- Increased Production Throughput: AI-enabled inline CT systems can process more parts per hour without compromising quality.

- Improved Process Optimisation: AI uses CT data to predict possible problems and optimise process parameters in additive and precision manufacturing.

- Improved Data Interpretation: AI speeds up complex measurements, CAD comparisons, and metrology tasks.

- Scalable and Repeatable Outcomes: AI guarantees consistent inspection criteria for various operators and facilities.

Conclusion

Inspection and quality control capabilities are being redefined by the collaboration between Industrial CT and AI. Industries can attain unprecedented throughput, sharper insights, and higher consistency by combining intelligent automation with detailed imaging capabilities. This integration represents the future of precision inspection for manufacturers who are forward-thinking, not just an improvement.

Xray Lab brings this future into focus — integrating advanced AI-driven CT inspection solutions that empower manufacturers to achieve unmatched precision, reliability, and speed across every stage of production.

Frequently Asked Questions

How Does AI Improve Industrial CT Reconstruction in Practice?

Deep learning models can increase imaging speed without compromising detail by reconstructing crisp, high-quality 3D volumes from fewer X-ray projections or low-dose scans.

Can Ai-Powered Industrial CT Systems Accurately Detect Tiny or Complex Defects?

Indeed. Even in difficult imaging situations, AI can inspect minute defects like microcracks, porosity, or inclusions with sensitivity on par with or better than humans.

What Are the Limitations or Risks of Using AI in CT Inspection?

Overfitting, “hallucinated” features, and possible misclassifications are among the risks that can be reduced with human oversight and validation datasets.

How Is AI Used for Dimensional Metrology and Reverse Engineering Workflows?

AI speeds up measurements and model creation by assisting with feature segmentation, noise reduction, and CAD alignment in CT-derived 3D point clouds.

What Role Does AI Play in Additive Manufacturing When Combined With CT Data?

AI models that optimise printing parameters, allow for in-line defect prediction, or adaptively modify manufacturing processes in real time can be fed CT-derived NDT data.