The advancement of quality inspection technologies AI and industrial computed tomography (CT) scanning has transformed practices in defect detection, product verification, and compliance within the manufacturing ecosystem.

The aerospace, automotive, electronics, and medical device industries face mounting challenges to inspection as products become denser and more intricate. The shortcomings of traditional inspection approaches, manual checks, 2D imaging, and basic algorithm-driven software guided systems, are becoming clearer. Microscopic and internal structural flaws go undetected and unaddressed.

Industrial CT scanning offers unparalleled accuracy and the ability to view external and internal features of components without destruction, giving 3D imaging with retrieval of high internal details. When combined with AI, imaging data can be processed with algorithms tailored for defect recognition to objectively and rapidly analyze the data.

The goal of this blog post is to discuss the relationship of CT and AI as partners in quality assurance, the industries embracing such technologies, and the impact of their adoption on precision manufacturing.

Table of Contents

What is Industrial CT?

Industrial computed tomography (CT) is a non-destructive imaging technique that uses X-rays to create detailed 3D models of both the internal and external structures of a part. Unlike 2D X-rays, which flatten internal details into a single view, CT generates volumetric images that allow for precise inspection of hidden flaws, such as porosity, cracks, voids, and inclusions.

The process involves rotating a component between an X-ray source and a detector to capture multiple images from various angles. These are then reconstructed using algorithms to form a high-resolution 3D dataset.

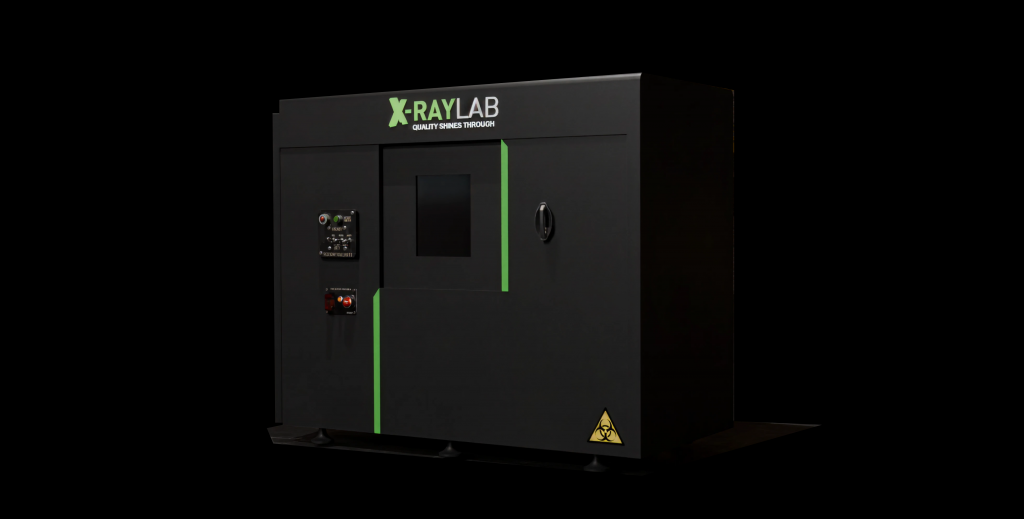

Xray-Lab’s advanced industrial CT system – combining high-resolution 3D X-ray imaging with AI-driven defect detection to reveal the unseen in castings, EV batteries, and medical devices.

Key Capabilities:

- Internal Defect Detection: Identifies hidden flaws invisible to surface inspection tools.

- Dimensional Measurement: Enables accurate metrology of internal geometries.

- Digital Twin Creation: Generates a 3D replica for CAD-to-part comparisons.

- Material Analysis: Highlights variations in density for composite and metal parts.

Real-World Use Cases:

- Aerospace: Scanning turbine blades for internal cracks.

- Automotive: Inspecting EV battery welds and castings.

- Medical Devices: Ensuring structural integrity of implants.

- 3D Printing: Verifying internal layer fusion and porosity.

How AI Enhances Visual Inspection

Artificial Intelligence (AI) is transforming quality inspection by automating the detection, classification, and analysis of defects, especially when dealing with high-resolution image data from industrial CT scans.

Traditional image analysis relies on static rules or thresholding, which often fails with complex materials, variable lighting, or ambiguous defects. Deep learning and artificial intelligence today allow systems to discern patterns from thousands of labelled data sets, replicating expert decisions, but on an order of magnitude and pace unimaginable to any human.

How It Works:

- Input Data: Industrial CT scans provide high-resolution pictures or volumetric slices which are given as input.

- Preprocessing: The images undergo cleaning, segmentation, and other processes to focus on the crucial parts.

- Analysis with Deep Learning: Complex patterns within the data are identified and classified with high precision by advanced models, like CNNs, using the scanned data.

- Output: Defect maps, classifications, and results with pass/fail are generated by the system, many times in real time.

Real-World Impact:

- The capability of inspection systems to address new or changing types of defects is possible due to the continuous learning processes of AI models.

- Some of the applications are recognizing small cracks in electronic components, detecting porosity in cast metal parts, and in the classification of weld defects on automobile components.

AI + CT: A Game-Changing Combo

What truly transforms quality inspection is not just AI or CT separately, but what occurs when they come together.

While industrial CT offers unmatched three-dimensional imaging of a product’s internal structure, the datasets generated are vast and intricate. Manual review of this information borders on the impossible.

That’s where AI steps in, making sense of the scans, automating analysis, and surfacing actionable insights within seconds.

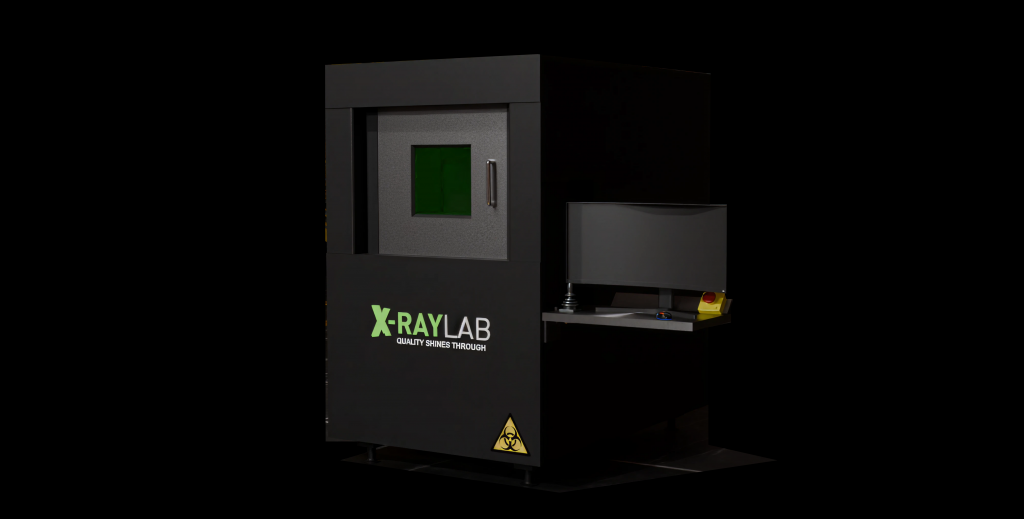

Xray-Lab’s compact CT inspection system – engineered for high-resolution imaging, space efficiency, and user-friendly operation, without compromising on accuracy.

Why the Combination Works:

- Speed at Scale: A single CT scan can contain thousands of image slices. AI processes this data at machine speed, making real-time inspection possible even in high-throughput environments.

- Detection of Subtle or Uncommon Defects: AI models trained on historical defect data can detect anomalies far too subtle or inconsistent for human inspectors or rule-based systems to catch.

- Quantitative Insights: Instead of simply flagging “pass” or “fail,” AI can measure defect size, location, density, and type, supporting root cause analysis and corrective actions.

- Adaptive Systems: As materials, designs, or processes change, AI models can be retrained, allowing the inspection system to evolve without hardware changes.

Industries Leading the Adoption

Several high-precision industries are rapidly adopting AI-powered industrial CT due to their need for flawless quality and deep internal visibility.

In aerospace, CT scanning combined with AI is now a standard for inspecting critical components like turbine blades, composite structures, and welded assemblies. These parts often operate under extreme conditions, and even a microscopic flaw can lead to failure. AI ensures rapid, reliable identification of such defects, while also supporting traceability and compliance.

Automotive manufacturers, particularly in electric vehicle (EV) production, use AI+CT to inspect battery modules, weld seams, castings, and complex assemblies. The internal detection of voids, misalignments, and even micro-cracks saves companies from expensive recalls, and supports safety protocols.

They also use this technology in the medical device industry for implants, syringes, and surgical tools. AI imaging checks confirm structural integrity and artificial intelligence helps in maintaining consistent quality throughout production batches, during even the most high-volume periods when checked manually.

Another industry that largely uses this technology is additive manufacturing—commonly known as 3D printing. Due to the intricate internal geometries of printed parts, computed tomography is used for verification in a layered manner. AI helps in the decision-making process for this and uses the data to assess for print errors, porosity, and deviations from the CAD model.

These industries not only adopt Artificial intelligence and computed tomography for quality assurance, they also use the data for predictive maintenance, design feedback, and process improvements throughout the product lifecycle.

The Future of Quality Inspection

Artificial Intelligence, along with Industrial Computed Tomography (CT) scanning, is guiding quality inspections processes toward smarter automation. In the future, we expect to see faster CT scanners combined with AI models that adapt to new defect types with minimum data input.

Immediate inspections on the edge will allow instant critique on production lines, enabling self-modifying systems. This will lead to very reduced downtimes. An inspection will now be an entire self-sufficient operation. All the steps will be taken from gathering information, analysis, and systems adjustments, to self-detect identifying issues and correcting them without disruption.

This will drastically change the manufacturing sectors leading to reduced defects, smarter, swift manufacturing, and automating quality checks.

Conclusion

The role of quality inspection changes from merely identifying defects to predicting, understanding, and removing them long before they occur. AI combined with industrial CT makes inspection an intelligent, proactive system that enhances speed, precision, and insight throughout the production process.

Every industry ranging from automotive to aerospace has started experiencing tangible benefits: quicker inspections, reduced mistakes, and more efficient decision-making. With ongoing advancements in technology, it does not only enhance but also redefines quality.

Xray-Lab uses AI-powered industrial CT inspection to provide manufacturers with deep insights that are usually concealed. The systems proficiently merge 3D X-ray imaging with smart defect discernment to ascertain structural integrity, dimensional precision, and defect-free output. Xray Lab offers EV battery, aerospace casting, and device inspections with meticulous and insightful quality assurance at unmatched speeds.

Frequently Asked Questions

What Internal Defects in EV Batteries Can X-Ray Inspection Detect?

Numerous internal flaws in lithium-ion EV batteries, such as electrode misalignment, weld voids, trapped gas pockets, foreign particles, and internal short circuits, can be found by X-ray inspection.

If left unnoticed, these defects may cause major issues like thermal runaway, overheating, or capacity loss.

Non-destructive X-ray imaging helps ensure that each cell meets stringent safety and performance standards before it reaches the consumer.

How Is Non-Destructive X-Ray Testing Used During EV Battery Production?

Non-destructive X-ray testing is employed inline during EV battery manufacturing to examine individual cells, modules, and entire packs without disassembling them.

It assists producers in minimising waste, detecting serious flaws in real time, and maintaining constant quality control without stopping production.

Large-scale EV manufacturing is supported by quick, automated screening made possible by high-resolution imaging and AI algorithms.

Can X-Ray Inspection Help Predict EV Battery Failures Before They Happen?

Yes. Modern X-ray systems can evaluate imaging data to find early warning indications of deterioration or failure by integrating AI and predictive analytics. Manufacturers can predict possible failure modes, optimise design, and apply proactive quality controls to produce safer, longer-lasting electric vehicle batteries by building digital twins and modelling battery behaviour.