Why Hairpin Weld Quality Matters in EV and Motor Manufacturing?

As electric motors become more compact and energy-efficient, the demand for precise and reliable hairpin weld analysis has increased significantly, especially in applications like electric vehicles (EVs) and high-performance industrial motors. These systems rely heavily on laser-welded copper hairpins to form crucial electrical connections within stators. Even minor internal weld flaws, misaligned geometry, or cracks can impact performance, raise thermal load, or accelerate system failure. To meet these needs, manufacturers are adopting X-Ray Inspection Technologies, XVOIDPRO, specially tailored for hairpin weld inspection, offering fast, and non-destructive evaluation during and inline on production lines.

Table of Contents

X-ray Inspection of Laser-Welded Copper Hairpins: Detecting Internal Defects

Hairpin welds need to be evaluated for a number of different defect types. Most importantly, for internal voids, foreign inclusions, and geometric deviations. These flaws may decrease conductivity, increase thermal resistance, or impose mechanical stress during operation of the motor. Modern imaging techniques and automated analysis systems, such as XVOIDPRO, allow for real-time defect detection and classification. This imaging software captures high-resolution X-ray scans and processes them to automatically highlight and quantify inconsistencies in the weld, thus verifying optimization and quality assurance strategies.

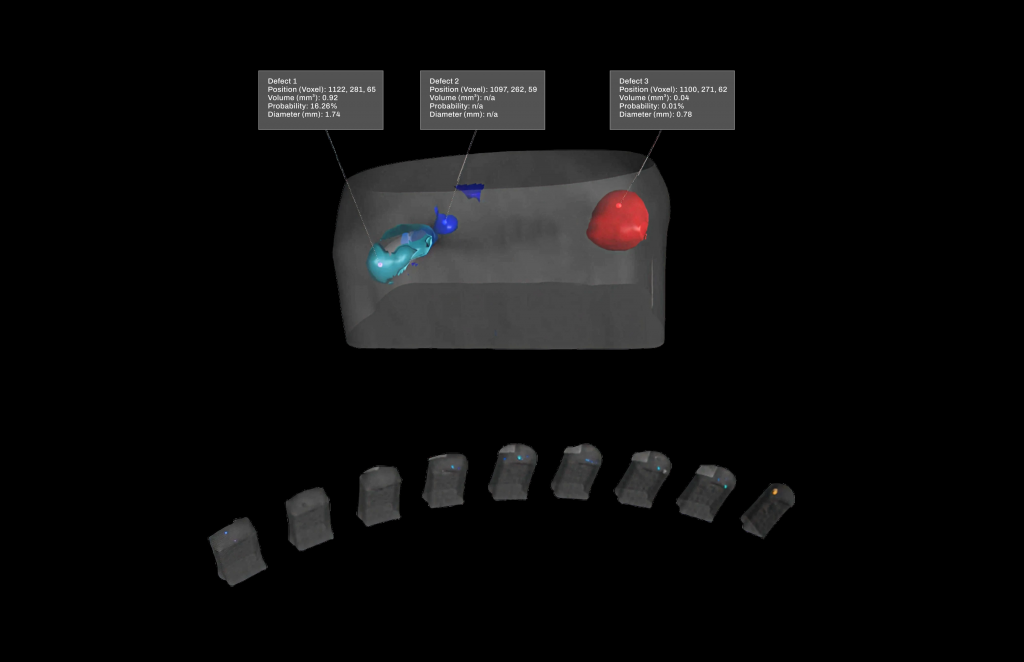

Figure 1. Automated X-ray defect detection in a copper hairpin weld using XVOIDPRO. 3D visualization showing internal voids and inclusions automatically identified by XVOIDPRO. Each color-coded marker represents a detected flaw with measured parameters. The visualization highlights XVOIDPRO’s precision in quantifying internal weld defects for quality control in EV motor manufacturing.

Non-Destructive Testing of Copper Hairpin Welds Using X-ray Imaging

Analyzing sealed or internal structures is a non-destructive process in X-ray-based weld inspection, which is a key advantage. For copper hairpins, which are often encased or wound within stator assemblies, inspection by means of visual or mechanical probing is of no value. In comparison, X-ray imaging is capable of revealing internal porosity or weld irregularities. With the aid of appropriate software, tools can flag voids, accentuate patterns of inclusion, and evaluate the weld shape against specified tolerances automatically, thereby reducing dependence on operators and improving reproducibility in high sample porosity.

Inline Hairpin Weld Quality Control with XVOIDPRO for Scalable Production

The inspection technology is useful on both extremes of the production continuum. During the R&D stage, engineers can leverage X-ray feedback for welding parameter optimization, joint type comparisons, or new material evaluation. Likewise, on the production floor, real-time quality control can be done using the same technology to scan each hairpin joint and notify the operators of any defects prior to assembly or shipment. Inline integration helps to strike the balance between high throughput and quality control for manufacturers.

In high-voltage motor applications, the detection of microvoids and inclusions is critical due to the potential for localized heating to cause early failures. Moreover, irregular welds can cause a lack of uniformity in the mechanical alignment or decrease the overall stability of the machine. Intelligent X-ray inspection systems with configurable software tools mitigate these risks by providing clear and repeatable inspection results which improve motor efficiency, reduce rework, and enhance traceability.

With the continued growth of the EV industry, advancements in motor technologies, and expanding applications, hairpin weld inspection technologies must evolve simultaneously. As with other aspects of modern manufacturing, it is crucial that continually operational inspection systems be designed for the intricate weld gaps to be checked without halting production.

Tools for automated X-ray analysis, such as XVOIDPRO, now provide a practical and scalable approach to meet these needs. These tools enhance reliability, reduce scrap rates, and improve long-term performance over a wide variety of applications.

Check out this quick video explanation.

Xray-Lab’s XVOIDPRO enables fast, non-destructive X-ray inspection of critical welds in electric motor manufacturing. It detects voids, inclusions, and geometric flaws with high precision. Ideal for both R&D and inline quality control. Learn more or contact us.

Frequently Asked Questions

Why Is X-Ray Inspection Important for Copper Hairpin Welds in EV Motors?

X-ray inspection stands as a critical safeguard for copper hairpin welds, surfacing hidden defects such as voids, cracks, and inclusions that visual and surface inspections inevitably miss.

In electric vehicle motors, a seemingly minor fault in a hairpin weld can ripple through the entire system, dampening electrical efficiency, triggering localized overheating, or precipitating premature failure. XVOIDPRO empowers manufacturers to pinpoint these vulnerabilities in their infancy, softly without damage, and in high throughput.

How Does Xvoidpro Enable Inline Weld Inspection on Production Lines?

XVOIDPRO delivers inline weld inspection by merging rapid X-ray imaging with smart, automated defect recognition. It captures every weld on the fly, spots internal defects like voids or inclusions, and notifies operators the moment an issue is detected, keeping the production line moving while ensuring every joint meets quality standards.

Can X-Ray Inspection of Hairpin Welds Replace Traditional Visual or Ultrasonic Methods?

Yes. In contrast to optical and ultrasonic inspection techniques, XVOIDPRO’s X-ray imaging delivers non-invasive visibility into concealed weld anomalies, such as ghost porosity and internal misalignments, thereby furnishing a more dependable approach to quality assurance.

Is AI Used to Enhance Defect Detection in Xvoidpro Systems?

Yes. Many advanced imaging systems now embed AI or deep learning techniques to separate genuine defects from clutter and noise. This not only enhances detection precision but also accelerates throughput, achieving results that align closely with seasoned human inspectors.

Why Is Hairpin Weld Analysis Critical for Electric Vehicle Motors?

Hairpin welds in electric vehicle stators conduct substantial currents while facing intense thermal cycling. Defects such as gas voids, misalignment, or incomplete fusion drive up electrical resistance, resulting in overheating and accelerating failure. XVOIDPRO verifies weld integrity by detecting these critical anomalies, thus enhancing overall motor efficiency and reliability.