Automotive manufacturers across the USA increasingly rely on industrial CT scanning and X-ray inspection to ensure the structural integrity of cast components. As parts become lighter, thinner, and more complex, traditional inspection methods often fail to reveal hidden defects. Computed tomography inspection in USA delivers unmatched 3D clarity—detecting porosity, inclusions, cracks, and dimensional deviations before they can cause failures.

Table of Contents

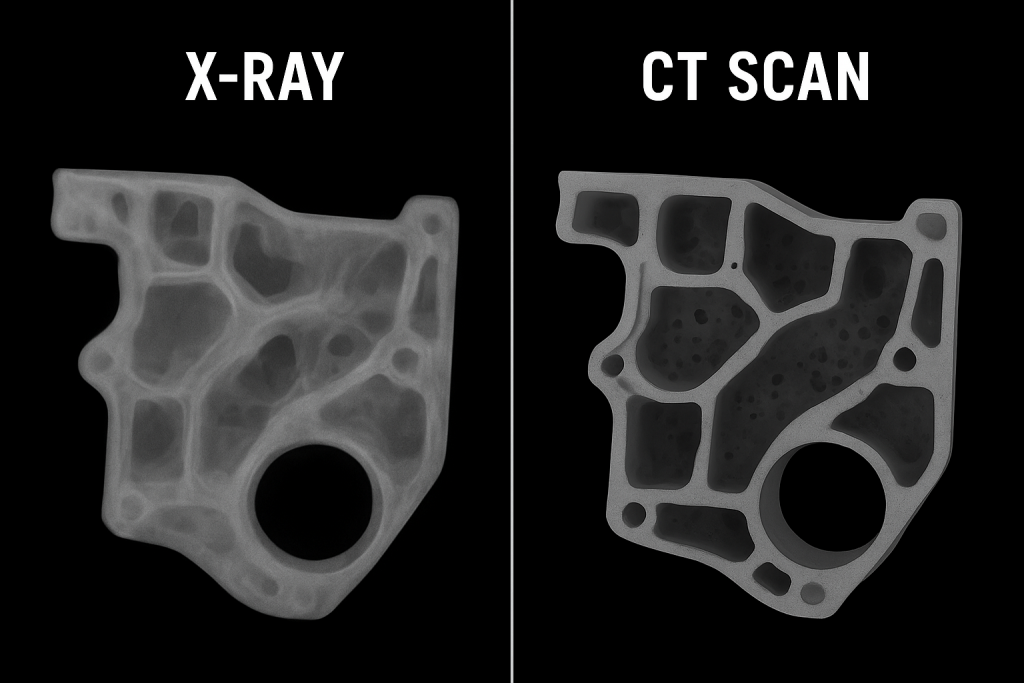

2D X-ray vs. CT scan of a lightweight automotive engine bracket casting, revealing internal lattice structures and porosity for optimized performance and reduced weight

Why CT Scanning Matters in Automotive Casting Inspection

CT scanning reconstructs a casting into a precise 3D model, revealing internal features at micron-level resolution. This is critical for safety-critical automotive parts such as engine blocks, transmission housings, EV battery enclosures, and structural supports. Compared to 2D X-ray, CT provides full volumetric insight, making it indispensable for NDT services and modern quality assurance.

Early Porosity Detection for Higher Reliability

Porosity is one of the most common casting defects. With 3D CT scanning services in USA can:

- Detect pore size, volume, and spatial distribution

- Differentiate between gas and shrinkage porosity

- Evaluate wall-thickness variations

- Compare measurements to CAD models

- Improve process control and reduce scrap

This level of detail ensures consistent part quality and improves yield.

Defect Visualization That Improves Manufacturing Decisions

Advanced industrial CT scanning in USA lets engineers visualize defects such as cold shuts, hot tears, voids, inclusions, micro-cracks, and warpage. This insight informs adjustments in gating, venting, cooling strategies, and tooling design to prevent defects at the source.

Failure Prevention Through Advanced Engineering Insights

CT data supports:

- Dimensional metrology and CAD comparison

- Reverse engineering for tooling or design updates

- Root-cause failure analysis

- Process validation for serial production

- Material flow and solidification studies

These insights help prevent field failures, minimize warranty claims, and ensure long-term durability.

Conclusion

Modern automotive manufacturing requires inspection methods that go beyond the surface. CT scanning and X-ray inspection provide the deep insight needed to detect defects, prevent failures, and ensure reliable production.

XRAY-LAB supports automotive casting quality by providing advanced industrial CT scanning services in USA, high-resolution X-ray inspection, 3D object scanning, and complementary NDT methods, including ultrasonic testing, eddy current testing, dye penetrant testing, and video inspection. Their services enable precise detection of porosity, cracks, inclusions, dimensional deviations, and structural inconsistencies in castings.

Frequently Asked Questions

What Is CT Scanning in Casting Inspection?

CT scanning uses X-rays to capture multiple 2D images of a casting from different angles, which a computer then reconstructs into a detailed 3D volumetric model. This helps in revealing hidden internal features like porosity, inclusions, cracks, and dimensional deviations without destroying the part.

How Does CT Scanning Prevent Casting Failures?

By identifying internal defects early, CT scanning helps engineers optimize casting processes, correct tooling issues, and prevent failures before the start of production (SOP) or service.

Is CT Scanning Better Than Traditional X-Ray?

Yes. Traditional X-ray offers a 2D view, while CT provides full 3D visualization for accurate defect detection.

Can Large Castings Be CT Scanned?

Yes. Modern industrial CT scanning in USA systems handle a wide range of part sizes, from small precision components to large engine blocks and structural housings.

What Other NDT Methods Support Casting Quality?

Ultrasonic testing, dye penetrant inspection, eddy current testing, and videoscopy complement CT scanning by detecting surface and subsurface defects that may not appear in X-ray.