Non-destructive testing (NDT) for Fiber Reinforced Polymers plays a critical role in ensuring the safety, reliability, and long-term performance of wind turbine blades across the United States and Europe. As wind energy projects expand and blade designs become larger and more complex, manufacturers and operators increasingly rely on advanced X-ray and computed tomography (CT) inspection to gain reliable insight into internal composite structures.

Table of Contents

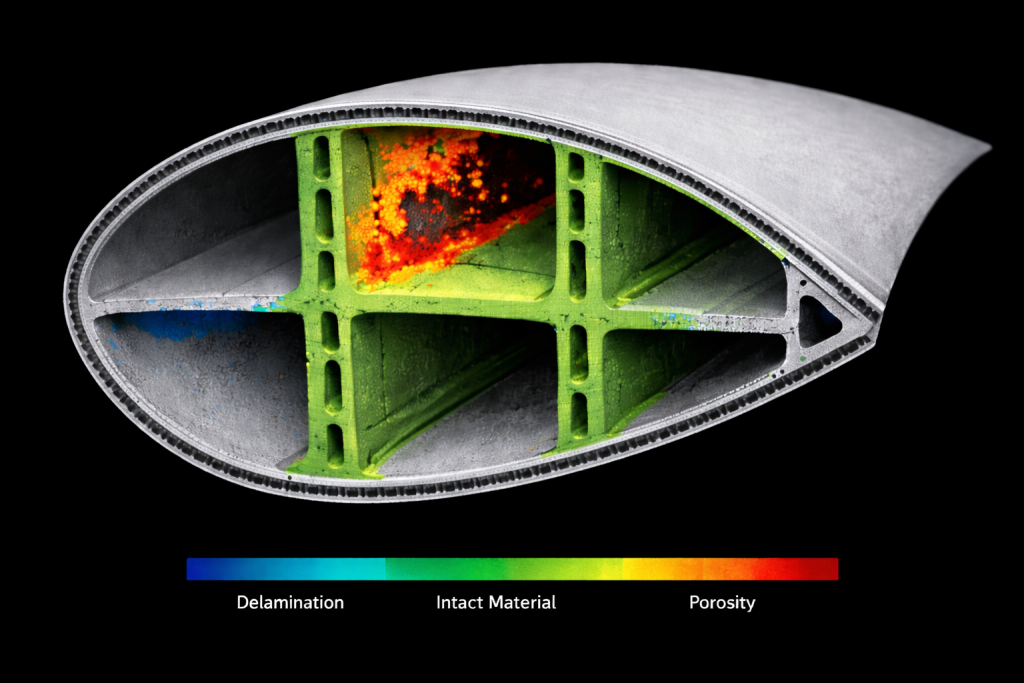

High-resolution industrial CT scan visualization of a GFRP wind turbine blade section, showing internal fiber structure and porosity

How Fiber Reinforced Composites Shape Modern Wind Turbine Blades

GFRP is widely used in wind turbine blades due to its material properties. Further, in U.S. and European wind energy projects, carbon fiber reinforced polymers are commonly applied in spar caps and other load-bearing blade sections to support longer spans and higher power output. While these materials enable performance gains, they also introduce inspection challenges, as internal defects are not visible from the surface.

Porosity, fiber misalignment, resin-rich areas, and internal delamination can significantly reduce structural integrity if left undetected. This makes reliable non-destructive inspection essential throughout manufacturing and service life.

Why Non-Destructive Inspection Is Critical for Wind Turbine Blades

Traditional destructive testing methods are impractical for large composite structures such as wind turbine blades. NDT allows internal evaluation without damaging the component, supporting both quality assurance and lifecycle management.

For GFRP/CFRP wind turbine blades, NDT helps:

- Confirm laminate quality during manufacturing

- Identify internal defects before blade installation

- Support root-cause analysis during failure investigations

- Enable data-driven maintenance and life-extension decisions

Using Industrial X-Ray and CT to Evaluate Wind Turbine Blade Integrity

Among available inspection technologies, industrial X-ray and computed tomography (CT) provide the most detailed insight into GFRP and CFRP structures. CT inspection enables full volumetric analysis, making it possible to evaluate internal features that cannot be assessed using surface-based techniques.

High-resolution CT scanning allows engineers to analyze:

- Internal voids and porosity distribution

- Fiber orientation, waviness, and layup consistency

- Subsurface cracks and delamination

- Resin flow behavior and material inconsistencies

For wind turbine blade components, CT data supports manufacturing optimization, certification processes, and detailed failure analysis. It is particularly valuable when inspecting critical blade sections where structural loads are highest.

Key Inspection Challenges in Large Wind Turbine Blades

Inspecting wind turbine blades presents several technical challenges, especially at industrial scale. Large component dimensions, complex curvature, and anisotropic composite behavior can all complicate defect detection and data interpretation.

Advanced X-ray and CT-based inspection address these challenges by providing consistent imaging across complex geometries and delivering quantitative data that supports engineering decision-making.

How X-RAYLAB Supports GFRP Wind Turbine Blade Inspection

X-RAYLAB specializes in industrial X-ray and computed tomography inspection for composite materials used in demanding applications such as wind energy. By focusing on high-resolution imaging and expert data interpretation, X-RAYLAB supports U.S.-based and European manufacturers and operators with reliable insight into wind turbine blade quality.

X-RAYLAB’s services enable:

- Accurate characterization of internal GFRP/CFRP defects

- Support for quality assurance and certification requirements

- Improved understanding of manufacturing process stability

- Informed decisions for maintenance, repair, and blade life extension

With extensive experience in advanced CT inspection, X-RAYLAB helps ensure that wind turbine blades meet the structural and reliability expectations of modern wind energy systems.

Frequently Asked Questions

What Types of Defects Can CT Detect in Wind Turbine Blades?

CT can identify internal porosity, fiber misalignment, delamination, cracks, and resin distribution issues that are not visible externally.

Why Is CT Preferred Over Surface-Based Inspection Methods for composite structures?

CT provides three-dimensional internal imaging, allowing full volumetric analysis of composite structures rather than limited surface or near-surface evaluation.

Can CT Be Used for Large Wind Turbine Blades?

CT is commonly applied to blade sections, critical components, and representative samples where detailed internal analysis is required.

How Does NDT Support Wind Turbine Blade Reliability?

By detecting internal defects early and supporting data-driven maintenance decisions, NDT helps reduce failure risk and extend blade service life.

How Does X-RAYLAB Support Composite Structure Inspections in the USA?

X-RAYLAB provides advanced industrial X-ray and CT inspection services, combined with expert analysis, to support composite quality assurance and failure investigation projects across the U.S. and Europa.