Weld integrity is critical in industries such as aerospace, automotive, energy, and heavy manufacturing. Even minor flaws like porosity, cracks, or incomplete fusion can compromise safety, reliability, and compliance. Advanced Non-Destructive Testing (NDT) ensures that welded parts are defect-free without damaging the components.

At Xray-Lab, we specialize in comprehensive NDT services for welded parts, offering state-of-the-art 2D/2.5D X-ray, Industrial Computed Tomography (CT) and advanced software-driven defect analysis. Our global clients benefit from accurate, fast, and fully traceable inspection solutions.

Table of Contents

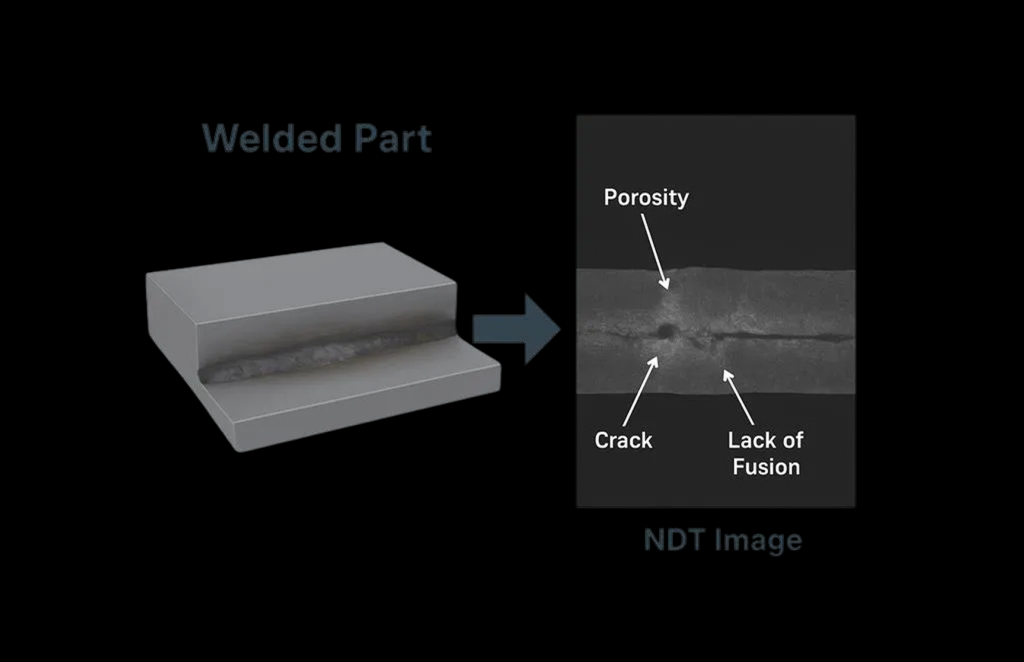

Welded part before inspection (left) and NDT scan results (right) showing porosity, cracks, and lack of fusion detected using advanced X-ray/CT techniques.

Key Weld Defects and Detection Methods

- Porosity Detection

Porosity occurs when gas becomes trapped during welding, forming voids that reduce mechanical strength.

Xray-Lab Detection Methods:

- 2D/2.5D X-ray: Fast imaging for surface and near-surface porosity.

- Industrial CT: 3D volumetric imaging for precise pore mapping and measurement.

- Ultrasonic Testing (UT): Detects subsurface voids in thick or complex welds.

- Crack Detection

Cracks can appear internally or on the surface and may propagate rapidly under stress.

Xray-Lab Detection Methods:

- CT Scanning: 3D visualization of internal cracks in complex weld geometries.

- Ultrasonic Testing: High-precision detection of planar cracks.

- 2D X-ray: Detects internal and surface-breaking cracks.

- Lack of Fusion & Incomplete Penetration

These defects occur when the weld metal fails to bond fully with the base material or adjacent passes.

Xray-Lab Detection Methods:

- Ultrasonic Testing (UT & Phased Array UT): Excellent for locating planar defects and measuring depth.

- Industrial CT: Shows density inconsistencies and bonding gaps with 3D resolution.

- 2D/2.5D X-ray: Efficient for detecting incomplete fusion in production settings.

Benefits of Xray-Lab NDT for Welded Parts

- High-resolution 3D visualization of internal weld structure

- Early defect detection, reducing rework and scrap

- Digital defect documentation and traceable reports

- Compliance with ISO, ASME, AWS, and industry standards

- Inspection of complex, large, or high-value components

- Integration with AI-based evaluation and inline CT systems for automated analysis

Xray-Lab leverages advanced CT, X-ray, ultrasonic testing, and software solutions to deliver reliable weld inspection services for industries worldwide.

Frequently Asked Questions

What Weld Defects Can Xray-Lab Detect?

Porosity, cracks, lack of fusion, incomplete penetration, and other internal or surface discontinuities.

Which NDT Method Is Best for Internal Weld Defects?

Industrial CT provides 3D volumetric analysis for internal defects; while ultrasonic testing is particularly effective for thick or critical welds.

Can Xray-Lab Inspect Large or Complex Welded Parts?

Yes, using LINAC XXL CT, RoboCT, and 2D/2.5D X-ray systems, we can inspect oversized or challenging geometries.

How Fast Are Xray-Lab Inspections?

2D/2.5D X-ray is ideal for fast production checks, whereas CT scanning delivers detailed 3D results along with comprehensive reporting.

Does Xray-Lab Provide Digital Documentation for NDT?

Yes, all inspections include high-resolution images, 3D reconstructions, and detailed defect reports to ensure traceability and quality assurance.